ARCHITIZER.COM

From Bold Promises to Subtle Precision: How 3D Printing Found Its Place in Architectural Detailing

Architects: Want to have your project featured? Showcase your work by uploading projects to Architizer and sign up for our inspirational newsletters.

“Entire House 3D Printed in 24 Hours,” “Robots Build Homes from Clay,” “World’s First 3D-Printed Neighborhood Launches.”

Remember these headlines? Unless you were living under a rock (a real or 3D-printed one, it doesn’t really matter), you probably saw a few of them a couple of years back.

For a moment, it seemed like 3D printing was about to revolutionize architecture. After all, it promised faster, cheaper and more sustainable construction at the push of a button. While the technology itself was not exactly new, this was the first time it was being taken seriously within the architecture world. Architects, engineers and tech enthusiasts alike described it as the new “it” tool of the built environment.

But as we can clearly see today (most of us still not living in 3D-printed houses and all), the radical transformation promised by those early experiments never quite took hold — at least not in the way people expected. That doesn’t mean the technology vanished, though. In fact, it’s been doing something arguably more impactful: finding its place not in printing entire buildings, but in refining their details.

This piece looks at how 3D printing entered the industry, why the early hype faded and how it’s now quietly (but successfully) proving its value in architectural design.

3D Printing Before It Was Cool

https://blog.architizer.com/wp-content/uploads/Robot_3D_print_timelapse_on_RepRapPro_Fisher.webm.720p.vp9_.webm

While it might’ve hit the architectural headlines in the 2010s, 3D printing has been around much longer. The technology first emerged in the 1980s as a tool for rapid prototyping in industrial design. Engineers used it to test product parts without the time and cost of traditional manufacturing. It wasn’t glamorous, but it was efficient, laying the groundwork for what would eventually become a game-changer across multiple industries.

Throughout the ’90s and early 2000s, 3D printing quietly expanded its reach. Aerospace and automotive companies began using it to develop lightweight parts. The medical field started experimenting with custom implants and prosthetics. Product designers loved it for the freedom it gave them to iterate quickly and test complex forms without expensive tooling.

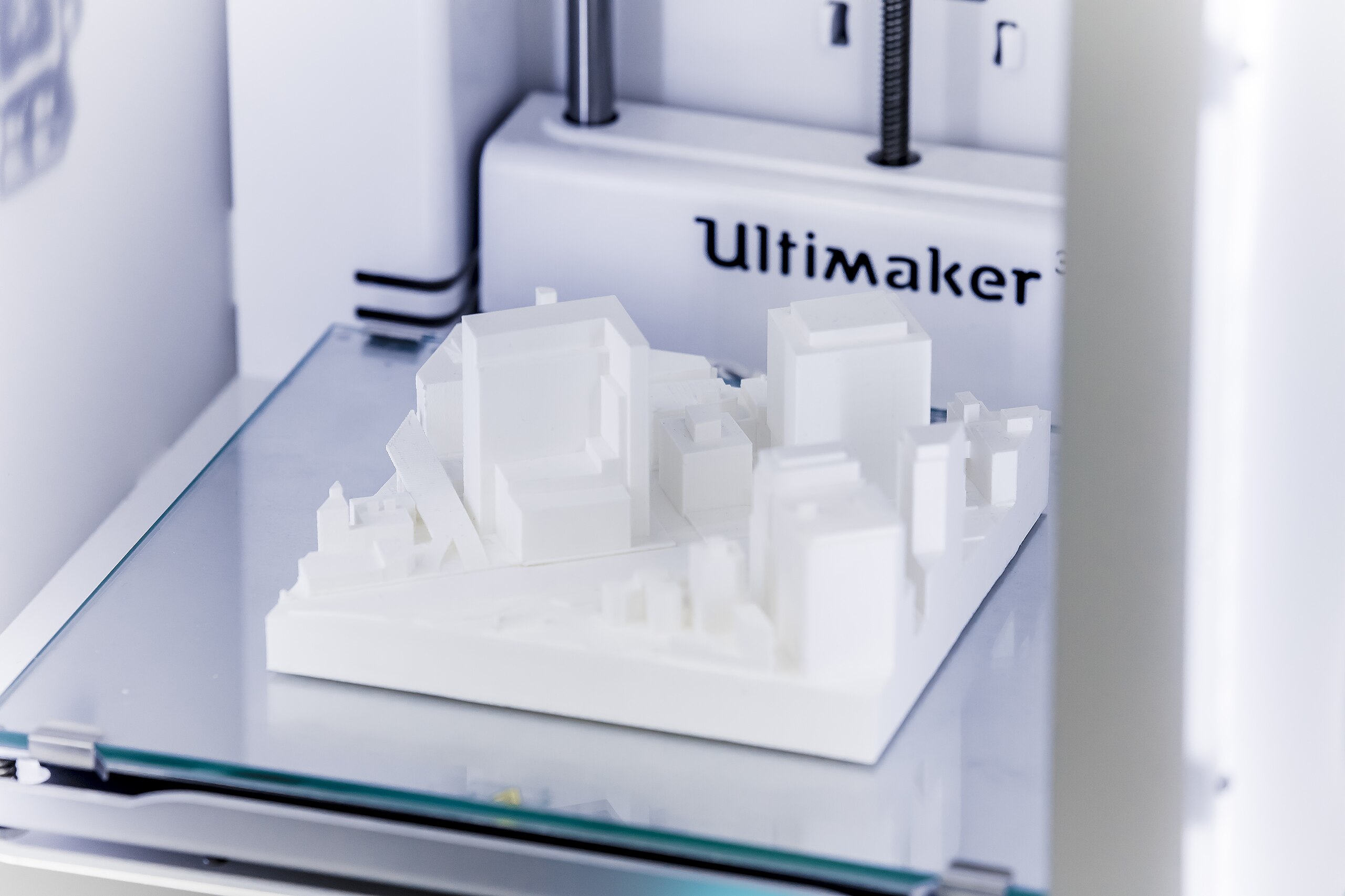

Svitlana Lozova, Architectural model printed with an Ultimaker 3D printer, CC BY-SA 4.0

Architecture, however, took a little longer to join the party. At first, 3D printing was mostly used behind the scenes for use cases like designing physical models, concept studies and competition entries. Still, at that point, it was a tool for visualization rather than construction. But as the machines got bigger and the materials more ambitious, architects started wondering what would happen if instead of just using this technology for printing models of buildings, they tried to use it for the real thing instead.

This started with early experiments like small pavilions, robotic clay extrusions and concrete wall prototypes in labs, which sparked a wave of curiosity and speculation. It felt like the beginning of something major. And in a way, it was.

The Rise and Fall of 3D-Printed Buildings

Once 3D printing caught the architecture world’s attention, the ambitions got big. Fast. The idea of printing entire buildings was being seriously pitched as a solution to urgent, real-world problems. It was positioned as a fix for challenges like the demand for fast, low-cost housing in disaster zones and the growing need for modular units in rapidly expanding cities, offering quicker builds, minimal labor and less material waste.

In 2017 construction company Apis Cor made headlines for printing a full house in just 24 hours using a mobile concrete printer. ICON, based in the U.S., focused on affordable housing, partnering with non-profits to 3D print homes in underserved communities.

Meanwhile, WASP in Italy developed machines that extrude locally sourced clay to print organic, zero-waste structures, even experimenting with off-grid, village-scale living.

The vision was bold and, for a while, genuinely exciting. But on the ground, the reality was more complicated.

For one, materials posed a problem. Most printed structures relied on a type of extruded concrete or clay (both materials that aren’t always great at handling insulation, structural loads or weathering on their own). Add to that the need to manually integrate plumbing, electricity, windows and finishes, and suddenly the “fully automated build” doesn’t look so fully automated.

Then there were regulatory issues. Building codes, zoning laws and permit processes were (and still are) created around traditional building methods. In many places, there simply wasn’t a framework to evaluate or approve a 3D-printed building.

And finally, there was the aesthetic and design challenge. While the layered, ribbed look of extruded concrete had a certain novelty at first, it quickly became repetitive. Customization was possible, but expensive. In practice, most printed buildings ended up looking like variations of the same idea.

So while the technology was promising, the systems around it weren’t ready to catch up. But the industry didn’t reject 3D printing; it just needed to figure out where it actually made sense. And as it turns out, that “sense” was hiding in the smaller, more intricate parts of buildings, not the shells themselves.

From Printing Buildings to Perfecting the Details

Ceramic House by Studio RAP, Amsterdam, Netherlands

Ceramic House by Studio RAP, Amsterdam, Netherlands

As the early excitement around large-scale 3D printing collided with reality, the limitations became clear.

But instead of abandoning the technology, architects and researchers began applying it where it could be more effective: producing components rather than entire buildings. The shift moved 3D printing from structure to detail, where precision, variation and small-batch production are not just acceptable but often preferred.

New Delft Blue by Studio RAP, Delft, Netherlands

This change aligned well with computational design tools. Parametric workflows allowed architects to generate hundreds of variations of a part, adapting geometry and pattern in response to environmental or structural inputs. 3D printing made it feasible to fabricate these non-standard components without molds or extensive tooling. The result was a growing interest in using the technology for cladding panels, tiles, joints and other expressive building elements.

Studio RAP has adopted this approach across multiple projects, using robotic 3D printing to produce ceramic façade systems with complex geometry. In New Delft Blue and Ceramic House, traditional glazing techniques are combined with digitally generated forms. Their other projects like Theater Zuidplein integrate ornamental surfaces and custom tiling directly into the architecture.

HiLo Unit at NEST by ETH Zurich, Block Research Group, Dübendorf, Switzerland

HiLo Unit at NEST by ETH Zurich, Block Research Group, Dübendorf, Switzerland

At ETH Zurich, the Block Research Group has explored 3D printing in structural and formwork systems. The HiLo Unit at the NEST building used lightweight printed formwork to cast optimized concrete shells. In Striatus, a 3D-printed masonry bridge designed by Zaha Hadid Architects was assembled without reinforcement or mortar, relying on compression-based design.

MX3D, known for robotic metal printing, created a full-scale pedestrian bridge in Amsterdam using printed steel components. The project demonstrated how metal additive manufacturing can be used for infrastructural elements with complex geometries.

In each of these cases, 3D printing did not aim to replace conventional construction but to support it, allowing for complexity, custom fit and material precision where it adds the most value.

A Quiet Success

What 3D printing has proven, over time, is that it doesn’t need to overhaul the construction industry to be valuable. It just needed to find the right scale. After all, the details of a project that give it texture, identity, or subtle complexity can be just as important as the building itself.

3D printing enables a level of ornamentation and material specificity that modern construction methods often struggle to justify. Tiles can respond to daylight patterns. Joints can follow parametric logic. Surfaces can be shaped to suit their context without relying on mass production.

Theater Zuidplein by Studio RAP, Rotterdam, Netherlands

This approach reflects broader shifts in architecture. There is a move toward circular design, a renewed interest in local materials and techniques, and a reliance on digital workflows that embrace variation and responsiveness. In that context, 3D printing no longer feels like a futuristic gimmick. It is simply a tool being used with purpose.

And as architectural practice continues to evolve, we’ll likely see even more creative, sustainable and integrated uses for 3D-printed details. Rest assured: the 3D printing revolution didn’t vanish. It just zoomed in.

Architects: Want to have your project featured? Showcase your work by uploading projects to Architizer and sign up for our inspirational newsletters.

The post From Bold Promises to Subtle Precision: How 3D Printing Found Its Place in Architectural Detailing appeared first on Journal.

0 Comentários

0 Compartilhamentos

48 Visualizações