WWW.FASTCOMPANY.COM

How Anthropologie saved 60,000 tons of plastic bags from going into landfills

These days, when you head to a shop to buy clothes, most brands package your purchases in a recyclable paper bag, which looks more eco-friendly than plastic.

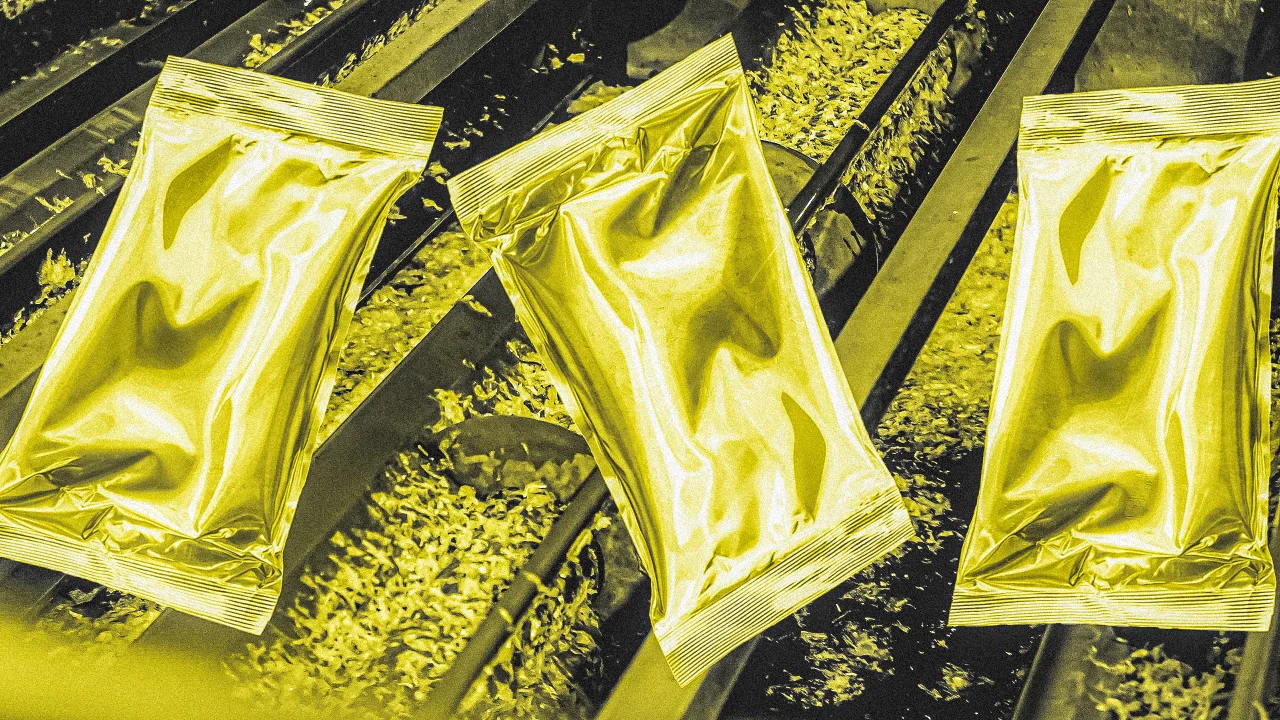

But behind the scenes—in back rooms that most customers never see—every single clothing retailer has enormous piles of flimsy plastic bags (sometimes called poly bags). These bags keep clothes clean as they travel across the complex global supply chain before arriving at the store. “We need to keep clothes in good condition as they move from factories to shipping containers to trucks,” says Candan Erenguc, chief operations officer at Anthropologie.

[Photo: WM/Anthropologie]

Most local recycling facilities don’t have the equipment to recycle poly bags, which are more complicated to break down than more solid plastics like water bottles. So most retailers simply send them in the regular waste stream where they will end up in a landfill. Since plastic does not biodegrade, these bags will break down into tiny fragments of microplastic that will end up in our waterways and food.

Anthropologie has been on a mission to find a way to recycle the poly bags it collects across its 215 retail stores. Over the past 18 months, it has partnered with Waste Management (WM), the largest recycling company in the United States, to develop a solution. Now, store associates collect these bags and send them to special facilities that are equipped to recycle them into other plastic products, extending their life.

Anthropologie has already recycled more than 60,000 tons of poly bags, which have been transformed into pellets that will be used to create other plastic items, including trash bags. “It has been a very seamless process, and we want to make sure other retailers know they can do it as well,” says Erenguc.

That said, things like trash bags cannot be further recycled, so they will eventually end up in a landfill. So it is still incumbent on brands to find ways to reduce the amount of plastic they consume and discard.

For decades, flimsy plastic bags have been a challenge for municipal recycling facilities that collect household waste. If you accidentally put them in your curbside recycling bin, they can clog up the recycling equipment, shutting the system down. As a result, people have been encouraged to simply dispose of these bags in the regular waste stream, where they will be landfilled or incinerated.

However, recycling technology is quickly improving, according to Tara Hemmer, chief sustainability officer at WM. For one thing, WM is now investing in robotics and computer vision technology that can better catch plastic bags that end up in the waste stream and separate them from the rest of the trash, so they don’t cause a major disturbance.

And perhaps more impressively, there are now several industrial recycling facilities across the U.S. that are specifically designed to recycle poly bags. Some of these plants are owned by WM. But there are also independent recyclers that partner with WM. “We work with our customers to make sure they can direct their waste to the right facility in our third-party network,” says Hemmer.

[Photo: WM]

Erenguc wanted to find a way to collect poly bags and ship them to these locations. However, as a major retailer, this presented a logistical challenge. It was also important for the process to be easy for employees to understand and follow. Each of Anthropologie’s 215 stores is staffed with dozens of employees who must be trained on best practices when it comes to waste disposal. Moreover, it was unclear where the nearest recycling facility would be for each store.

“We didn’t want to be transporting poly bags back and forth across the country, because that isn’t good for the environment either,” Erenguc says.

But this is where WM could help. Anthropologie brought in members of the WM team to study the situation and come up with a solution that would be easy for retail employees to adopt. WM identified the address of the closest recycling facility for each store. Retail associates now collect plastic bags and when they have achieved a certain volume, they ship them out to a designated facility. The recycling plants turn poly bags into pellets that can than be used to create other products.

“It’s such a streamlined solution,” Erenguc says. “It was so easy to execute, but we’ve already managed to divert 60,000 pounds of plastic from landfills.”

[Photo: WM]

Hemmer says that many retailers are eager to divert waste from landfill. While there’s been a narrative that companies have abandoned their sustainability goals, that hasn’t been her experience. “We’ve found that companies still have goals and are marching towards them,” she says. “And consumer product companies are trying to increase the amount of recycled content that goes into their products.”

Hemmer says that recycling technology is improving every year. WM is currently working to make it possible to recycle plastic bags in residential areas, beginning with a plant in Chicago that will reach about 3,500 households.

But often the obstacle to bringing about change at scale isn’t technological—it’s logistical. People, as well as companies, are more likely to adopt new processes if they’re simple. “Part of our job is to help troubleshoot,” says Hemmer. “But diverting waste from landfill is actually a lot easier than you’d imagine.”

0 Kommentare

0 Anteile

32 Ansichten