Superwood aims to replace steel and concrete with a sustainable alternative

Forward-looking: As InventWood prepares to bring its first batches of Superwood to market, it stands as a testament to what can happen when scientific innovation meets entrepreneurial determination. If successful, Superwood could mark a turning point in the quest for greener, stronger, and more beautiful buildings.

What began as a laboratory experiment at the University of Maryland is now poised to significantly influence construction practices. InventWood, a startup spun out of the university, is preparing to launch a new material known as Superwood – a wood-based product engineered to have a strength-to-weight ratio nearly ten times greater than steel, yet lighter and more sustainable.

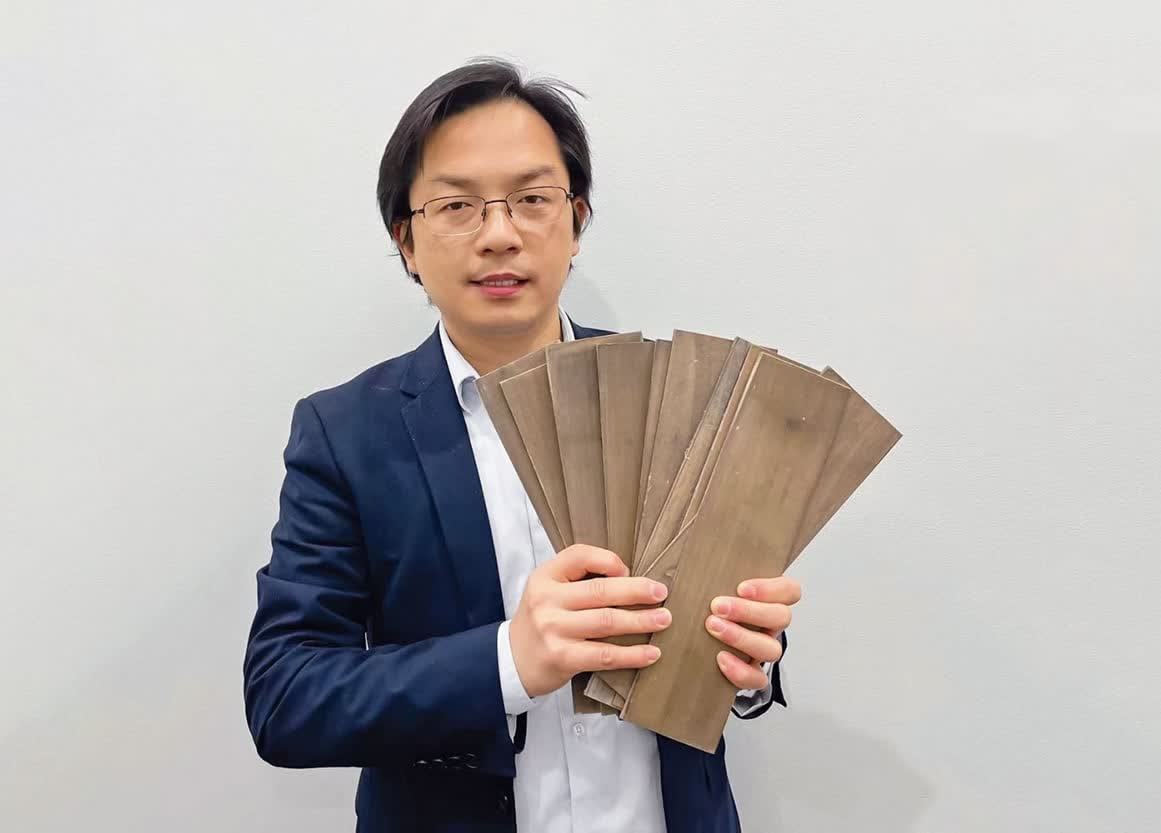

The story began in 2018, when Dr. Liangbing Hu, a materials scientist at the University of Maryland, developed a patented technique that transforms ordinary timber into a material up to 12 times stronger and 10 times tougher than its original form.

Instead of letting the discovery languish in academic obscurity, Dr. Hu further refined his technique, dramatically reducing the production time from over a week to just a few hours.

Recognizing its commercial potential, Dr. Hu licensed the technology to InventWood, which is now led by CEO Alex Lau. With million recently secured in a Series A funding round, the company is preparing to open its first commercial production facility in Frederick, Maryland. Shipments of Superwood are scheduled to begin in the third quarter of 2025.

Superwood's innovation lies in its molecular engineering. The process starts with ordinary wood, which is mostly composed of cellulose and lignin. By selectively removing certain components and applying "food industry" chemicals, InventWood strengthens the cellulose fibers, then compresses the material to increase the hydrogen bonds between molecules.

// Related Stories

This new material is not just strong, it's also highly functional. Superwood is resistant to fire, water, rot, and pests. It retains the natural warmth, texture, and beauty of wood, and with some polymer treatment, can be used for outdoor applications like siding, decking, and roofing.

Initially, InventWood will focus on producing facade materials for commercial and high-end residential buildings. But the company's ambitions go further. Lau envisions a future where structural beams and other building components are made from Superwood, offering architects and builders a material that is not only high-performing but also environmentally responsible.

The environmental benefits are significant. The construction industry is a major contributor to global carbon emissions, largely due to its reliance on concrete and steel. By offering a domestically sourced, sustainable alternative, InventWood aims to reduce the industry's carbon footprint while supporting American manufacturing and local economies.

The company has also formed a strategic partnership with Intectural, a leading distributor of architectural materials, to accelerate Superwood's adoption across North America.

InventWood's progress has attracted support from both public and private sectors, including the US Department of Energy, the Department of Defense, and several climate-focused investment groups. Environmentalist and entrepreneur Paul Hawken has called Superwood "an extraordinary breakthrough that exalts the genius of the natural world," predicting it will play a pivotal role in the future of global construction.

#superwood #aims #replace #steel #concrete

Superwood aims to replace steel and concrete with a sustainable alternative

Forward-looking: As InventWood prepares to bring its first batches of Superwood to market, it stands as a testament to what can happen when scientific innovation meets entrepreneurial determination. If successful, Superwood could mark a turning point in the quest for greener, stronger, and more beautiful buildings.

What began as a laboratory experiment at the University of Maryland is now poised to significantly influence construction practices. InventWood, a startup spun out of the university, is preparing to launch a new material known as Superwood – a wood-based product engineered to have a strength-to-weight ratio nearly ten times greater than steel, yet lighter and more sustainable.

The story began in 2018, when Dr. Liangbing Hu, a materials scientist at the University of Maryland, developed a patented technique that transforms ordinary timber into a material up to 12 times stronger and 10 times tougher than its original form.

Instead of letting the discovery languish in academic obscurity, Dr. Hu further refined his technique, dramatically reducing the production time from over a week to just a few hours.

Recognizing its commercial potential, Dr. Hu licensed the technology to InventWood, which is now led by CEO Alex Lau. With million recently secured in a Series A funding round, the company is preparing to open its first commercial production facility in Frederick, Maryland. Shipments of Superwood are scheduled to begin in the third quarter of 2025.

Superwood's innovation lies in its molecular engineering. The process starts with ordinary wood, which is mostly composed of cellulose and lignin. By selectively removing certain components and applying "food industry" chemicals, InventWood strengthens the cellulose fibers, then compresses the material to increase the hydrogen bonds between molecules.

// Related Stories

This new material is not just strong, it's also highly functional. Superwood is resistant to fire, water, rot, and pests. It retains the natural warmth, texture, and beauty of wood, and with some polymer treatment, can be used for outdoor applications like siding, decking, and roofing.

Initially, InventWood will focus on producing facade materials for commercial and high-end residential buildings. But the company's ambitions go further. Lau envisions a future where structural beams and other building components are made from Superwood, offering architects and builders a material that is not only high-performing but also environmentally responsible.

The environmental benefits are significant. The construction industry is a major contributor to global carbon emissions, largely due to its reliance on concrete and steel. By offering a domestically sourced, sustainable alternative, InventWood aims to reduce the industry's carbon footprint while supporting American manufacturing and local economies.

The company has also formed a strategic partnership with Intectural, a leading distributor of architectural materials, to accelerate Superwood's adoption across North America.

InventWood's progress has attracted support from both public and private sectors, including the US Department of Energy, the Department of Defense, and several climate-focused investment groups. Environmentalist and entrepreneur Paul Hawken has called Superwood "an extraordinary breakthrough that exalts the genius of the natural world," predicting it will play a pivotal role in the future of global construction.

#superwood #aims #replace #steel #concrete

0 Σχόλια

·0 Μοιράστηκε

·0 Προεπισκόπηση