Introducing Xstrings: MITs New Bionics 3D Printing Method

3dprintingindustry.com

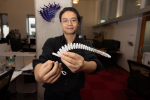

Researchers from MITs Computer Science and Artificial Intelligence Laboratory (CSAIL), Zhejiang University, and Tsinghua University have developed a new approach for 3D printing objects capable of humanlike movement. Called Xstrings, the method automates the fabrication of cable-driven assemblies that can bend, coil, screw, and compress.Such devices are traditionally difficult to produce because the cable must be manually embedded throughout the object. However, the Xstrings method leverages multi-material FDM 3D printing to embed cables directly within the structure in a single step, eliminating manual assembly requirements. The team has also developed a digital design tool that allows users to generate 3D print files of cable-driven components with desired movement capabilities.Jiaji Li, lead author, and MIT CSAIL postdoc, will present the new research paper during next months 2025 Conference on Human Factors in Computing Systems (CHI2025). It outlines several tests used to validate Xstrings capabilities. For instance, Lis team confirmed that the 3D printed cables survived over 60,000 90-degree contractions before breaking. Additionally, production speed impacted cable quality, with 10 mm/s and 15 mm/s yielding optimal results when 3D printing at 260C. According to Li, Xstrings can reduce total production time by 40%.Ultimately, the researchers believe their new approach offers value for applications including cable-driven robots for space stations and extraterrestrial bases, bionic devices, adjustable fashion designs, and interactive artwork installations.The Xstrings software can bring a variety of ideas to life. It enables you to produce a bionic robot device like a human hand, mimicking our own gripping capabilities, Li explained. Our innovative method can help anyone design and fabricate cable-driven products with a desktop bi-material 3D printer.Jiaji Li and a device 3D printed using the Xstrings method. Photo via MIT CSAIL.MIT introduces new bionics 3D printing methodCable-driven mechanisms function by threading a wire through a segmented object. Pulling the wire creates tension, causing the object to bend, twist, or fold, depending on its design. Such approaches are frequently used in bionics, allowing robotic devices to exhibit anthropomorphic movement. For instance, adding cables to a robotic hand can enable the fingers to curl and grip objectsMITs Xstrings software uses Rhinoceros 8 as its design environment and Grasshopper as an intermediary computational tool. The workflow begins with a user submitting a design with specific dimensions. They then choose one of four motion primitives, Bend, Coil, Twist, or Compress, to define how their device will move. Users can also input the desired angle for these motions.Notably, multiple primitives can be combined into a single device to unlock greater motion capabilities. For instance, when creating a robotic claw, the researchers integrated multiple cables in a parallel combination, allowing each finger to close into a fist. They used their Xstrings method and design tool to 3D print several other multi-material mechanisms. These included a walking lizard robot, a wall sculpture that can be opened and closed, and a tentacle that can coil around objects.Xstrings also allows users to determine where each cable is secured within their parts. This includes selecting the endpoint where the cable is fixed (the anchor), the holes the cable passes through (threaded areas), and where the cable is pulled to operate the device (the exposed point). For example, a robotic finger might include an anchor at the fingertip and a cable that runs down the finger to an exposed pull tag at the other end.After simulating the design, users can export their files and send them to an FDM 3D printer. To ensure compatibility with any multi-material FDM 3D printer, the researchers chose not to generate G-code for a specific model. Instead, Lis team has provided parameter settings for various slicing software and 3D printed their Xstrings test devices using an UltiMaker S5, UltiMaker 3, and Bambu Lab X1. They fabricated the main body of each device with PLA and used Nylon filament for the cable.MITs new process creates functional parts in a single step by positioning horizontal cables and printing around them. So far, this method has been used to produce parts with a rigid exterior and a soft, flexible interior. In the future, the researchers aim to reverse this structure by 3D printing devices with a soft exterior and a rigid interior, mimicking human skin and bones. They also plan to explore more durable cables and experiment with embedding them at different angles or vertically.Li co-authored the paper with Shuyue Feng, a masters student at Zhejiang University, and Yujia Liu from Tsinghua University. Guanyun Wang, an assistant professor at Zhejiang University and former MIT Media Lab visiting researcher, also contributed. The team included three CSAIL members: Maxine Perroni-Scharf, an MIT PhD student in electrical engineering and computer science, and Emily Guan, a visiting researcher. Senior author Stefanie Mueller is the TIBCO Career Development Associate Professor at MIT in Electrical Engineering, Computer Science, and Mechanical Engineering.An Xstrings 3D printed cable-driven finger. Image via MIT CSAIL.3D printing bionics3D printing is being increasingly adopted to fabricate bionic devices, particularly for prosthesis applications.Earlier this month, researchers from Johns Hopkins University, Florida Atlantic University, and the University of Illinois Chicago developed a 3D printed prosthetic hand that mimics human touch. The new offering combines rigidity and dexterity, boasting a grip strong enough to securely hold a water bottle and delicate enough to pick up a fragile plastic cup without damaging it.Its hybrid robotic fingers feature three independently actuated soft joints made by chemical manufacturing firm Smooth-Ons Dragon Skin 10 silicone. These are supported by rigid skeletal structures 3D printed in PLA. Analysis and testing have reportedly shown that each hybrid robotic finger can achieve 130 curvature and a flexion angle of 208 at an actuation pressure of just 7 psi. This is more efficient than purely soft robotic fingers which require much higher pressures. In fact, during testing, the hybrid finger demonstrated over three times the grasping force of soft robotic alternatives.Last year, UK-based robotics company Open Bionics announced that a hand amputee from London had adopted its 3D printed finger device for the first time. The prosthesis called the Hero Gauntlet, helps people with congenital or acquired partial hand-limb differences regain hand functionality. Open Bionics customizes each device using 3D scanning and additive manufacturing technology. Users control the gripping action by flexing their wrists.In other news, US-based prosthesis manufacturer Psyonic developed a 3D printed Bionic Hand using Formlabs Form 3 stereolithography (SLA) 3D printer. The development process included rapid prototyping, design iterations, and low-volume production of end-use parts. The Ability Hand weighs just 490 grams. Its thumb rotates electrically and manually, while all five fingers can flex to provide full hand functionality.Who won the 2024 3D Printing Industry Awards?Subscribe to the 3D Printing Industry newsletter to keep up with the latest 3D printing news.You can also follow us on LinkedIn, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.Featured image shows Jiaji Li and a device 3D printed using the Xstrings method. Photo via MIT CSAIL.

0 Comments

·0 Shares

·62 Views