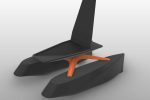

Royal3D unveils its new ShearWater Aquatic Drone for maritime applications

Dutch 3D printing service provider Royal3D has introduced the ShearWater Aquatic Drone, a new prototype designed to tackle various challenges in maritime and heavy-duty applications.

Developed for maintenance and surveillance tasks, ShearWater brings together large format additive manufacturing (LFAM) and durable materials to deliver reliable performance even in demanding maritime environments. Made entirely from recycled and recyclable materials, the drone is intended to minimize environmental impact without compromising functionality. Its modular and parametric design allows companies to tailor the system to their specific needs, enhancing safety and productivity across various maritime environments.

“What sets Royal3D apart is our ability to adapt advanced 3D printing technologies for industries like maritime and heavy-duty manufacturing, where the demands on strength and durability are unparalleled,” says Fulko Roos, Founder of Royal3D and maritime transportation company Royal Roos.

Additionally, the Rotterdam-based company is hosting an event for World Boating Day on May 24th and “we will be showing the drone printing to our participants.” The event is free of charge and interested readers can register or contact Royal3D.

The ShearWater Aquatic Drone. Image via Royal3D.

Precision-built for harsh maritime environments

Built using specially developed thermoplastic polymers and PETG fiber-reinforced materials, the aquatic drone offers a combination of strength, stiffness, and impact resistance while remaining lightweight and watertight. Royal3D’s proprietary 3D printing process, which relies on InfraRed cameras to precisely control layer adhesion, is central to the drone’s structural integrity and performance. According to the company, the 3D printing process also integrates Royal3D’s IP knowledge, enhancing the drone’s durability and reliability.

The ShearWater project, partially funded through the EU Crossroads initiative, combines AI-powered maritime solutions designed to improve safety and operational efficiency for people and wildlife during port inspections and other marine activities. Through participation in this project, Royal3D has been able to enhance its drone technology, specifically by boosting efficiency and using more sustainable materials.

With more than a decade of experience in large-scale AM, Royal3D specializes in producing robust components such as transport cradles, structural elements, and customized industrial parts. Operating two of the largest 3D printers in Europe, the company continues to meet the demands of various sectors by delivering components suited to heavy-duty applications.

Although “our expertise in urban design and architectural applications continues to deliver innovative solutions across diverse sectors,” Royal3D’s current focus on maritime and industrial manufacturing reflects broader efforts to enhance material efficiency and expand design capabilities. Meeting the increasing demand for reliable, customizable solutions within the maritime sector is a priority.

The ShearWater Aquatic Drone (white). Image via Royal3D.

3D printed drones for maritime use

As observed before, 3D printed drones have long been used for surveillance, vessel maintenance, and other potential maritime applications. Back in 2017, Sembcorp Marine (SM), in partnership with DNV GL, SIMTech, and NAMIC, signed a memorandum of understanding (MoU) to enhance maritime operations through drone-assisted inspections and digital twin technology.

DNV oversaw the deployment of drones programmed to assist surveyors with close-up inspections of ship structures, providing detailed data on vessel conditions and improving personnel safety in hazardous environments. Part of a broader effort to integrate drones with AM and digital twins, this initiative aimed to optimize ship designs and streamline maintenance processes at SM’s Tuas Boulevard Yard, supporting Singapore’s Advanced Manufacturing and Engineering strategy.

A year before that, the British Royal Navy launched a 3D printed Unmanned Aerial Vehicle (UAV) called SULSA from the HMS Protector to aid ice patrol navigation in the Antarctic.

Built by the University of Southampton using laser sintering technology, SULSA provided aerial surveillance by relaying images from above, demonstrating effective maritime patrol capabilities with potential applications in weapon targeting and communication. This approach aligned with broader efforts to integrate 3D printed drones for various maritime operations, including inspection, maintenance, and data collection.

What 3D printing trends should you watch out for in 2025?

How is the future of 3D printing shaping up?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Featured image shows the ShearWater Aquatic Drone. Image via Royal3D.