3DPRINTINGINDUSTRY.COM

Fortify, Notre Dame, and RTX Selected for Army 5G GRIN Antenna Prototype Contract

Fortify, a Boston-based manufacturer of radio frequency (RF) and microwave (MW) devices using a patented fabrication platform, has been awarded a U.S. Army contract to improve Command and Control (C2) systems through advanced 5G infrastructure. The project is backed by the Army’s Command, Control, Communication, Computers, Cyber, Intelligence, Surveillance and Reconnaissance (C5ISR) Center and involves collaboration with RTX, a defense company specializing in radar and communication systems, and the University of Notre Dame’s Microwave and Millimeter-wave Circuits and Systems Laboratory.

The team will deliver a prototype GRadient-INdex (GRIN) lens antenna system tailored for 5G tactical networks. Fortify’s platform, which is based on high-precision dielectric manufacturing and may involve additive techniques, will be used to fabricate the antenna. Testing will be conducted by the Army’s Combat Capabilities Development Command (DEVCOM), which oversees technology solutions related to military communications and signal processing. The objective is to increase bandwidth and gain while minimizing latency, meeting strict Army performance requirements for mobile deployments.

“This contract presents a significant opportunity for Fortify to demonstrate the disruptive potential of our GRIN lens technology,” said Karlo Delos Reyes, Chief Customer Officer and Co-Founder of Fortify. “By leveraging our expertise in dielectric lensing, we are pushing the boundaries of what’s possible in tactical communications, ensuring more resilient and high-performance solutions for the warfighter.”

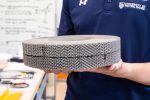

A prototype GRIN lens structure developed in collaboration with the University of Notre Dame for use in tactical 5G antenna systems. Photo via Fortify.

Fortify’s passive lensing system aims to replace current C2 architectures that rely on fixed, wired connections—an approach that restricts operational flexibility in high-stakes environments. The prototype is designed to be wireless, energy-efficient, and suitable for mobile applications, where traditional infrastructure is impractical. Passive dielectric lensing modifies signal paths without active electronics, which can reduce power demands and improve reliability under combat conditions.

Researchers Dr. Patrick Fay and Dr. Jonathan Chisum of the University of Notre Dame are supporting the antenna design and testing phase. Both have prior Department of Defense research experience and previously collaborated with Fortify on defense-related programs. Their academic lab specializes in RF component design, millimeter-wave systems, and integrated circuit modeling. The partnership leverages Notre Dame’s domain expertise alongside Fortify’s proprietary platform to accelerate the development timeline.

Josh Martin, CEO and Co-Founder of Fortify, emphasized the strategic significance of the collaboration. “We’re thrilled to be working alongside Notre Dame and RTX to bring next-generation tactical communication systems to life,” he said. “This effort reinforces our commitment to supporting the warfighter with technology that enhances both mission effectiveness and survivability.”

MQ-9 Reaper UAV – an unmanned drone used by the US Military. Photo via Department of Defense.

Defense Manufacturing Investments

The U.S. Department of Defense has steadily increased investments in additive manufacturing and materials research to enhance military readiness and autonomy. In March 2025, Supernova Industries Corp, an advanced manufacturing company based in Austin, Texas, secured a $2 million subcontract from the American Center for Manufacturing & Innovation (ACMI) to develop energetic materials using its proprietary Viscous Lithography Manufacturing (VLM) process. The company’s method enables the use of high-viscosity polymers to produce dense components for defense applications such as rocket motors and explosives—areas where traditional 3D printing methods fall short. The award was issued through the DoD’s MCEIP Pathfinders initiative and reflects a growing emphasis on adopting new fabrication platforms capable of meeting strict performance and safety requirements for national defense systems.

Parallel efforts have focused on securing domestic sources of strategic metals. In early 2025, IperionX, a U.S. materials firm, was awarded up to $47.1 million by the DoD to develop a vertically integrated titanium supply chain. The initiative aims to reduce American dependence on foreign-controlled sources of titanium, currently dominated by China, Japan, and Russia. Funding from the Industrial Base Analysis and Sustainment (IBAS) program supports both the Titan Critical Minerals Project in Tennessee and a titanium manufacturing campus in Virginia. IperionX’s proprietary processes—HAMR™ and HSPT™—offer a domestic pathway for producing cost-effective titanium components with defense-grade performance.

IperionX’s Titanium Manufacturing Campus in Virginia. Photo via IperionX.

Ready to discover who won the 20243D Printing Industry Awards?

Subscribe to the 3D Printing Industry newsletter to stay updated with the latest news and insights.

Featured image showcase a prototype GRIN lens structure developed in collaboration with the University of Notre Dame. Photo via Fortify.

Anyer Tenorio Lara

Anyer Tenorio Lara is an emerging tech journalist passionate about uncovering the latest advances in technology and innovation. With a sharp eye for detail and a talent for storytelling, Anyer has quickly made a name for himself in the tech community. Anyer's articles aim to make complex subjects accessible and engaging for a broad audience. In addition to his writing, Anyer enjoys participating in industry events and discussions, eager to learn and share knowledge in the dynamic world of technology.

0 Comentários

0 Compartilhamentos

25 Visualizações