3D Printing Industry Awards Start-up of the Year nominee 3D Architech

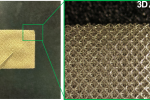

Data center cooling and hydrogen production for clean energy are just two applications for the technology developed by 3D Printing Industry Start-up of the Year nominee 3D Architech. This start-up is focused on metal manufacturing based on proprietary gel-based 3D printing technology, enabling scalable production of metal components with exceptionally fine, micron-scale features. This innovation allows for intricate designs and optimized structures that enhance device performance across various industries.Kai Narita, CEO and founder of 3D Architech told 3DPI more about the company.3DA micro-architected nickel lattice for water electrolyzer. Photo via 3D Architech.3DPI: What problem are you solving, and why is it important?Kai Narita: We tackle high electricity costs in data center cooling and inefficiencies in hydrogen electrolyzer output. Cooling consumes up to 40% of data center electricity, creating significant financial and environmental burdens, while hydrogen costs need to drop by 80% for global carbon-neutral adoption. Our gel-based metal additive manufacturing and micro-architected designs achieve up to 60% cooling energy savings and boost electrolyzer output by 30%, delivering substantial cost savings and advancing sustainability goals.3DPI: Who is your target market?Kai Narita: Our target market includes data center hyperscalers, AI chip manufacturers, cooling device manufacturers, and water electrolyzer producers. These sectors demand high-efficiency cooling and energy solutions. Were establishing strategic partnerships in Japan and the U.S. to scale globally.3DPI: Who are the founders and core team members, and what is their experience in this industry?Kai Narita: Our team comprises 15 members, including 8 PhDs from Caltech, Harvard, and MIT, bringing deep expertise in micro-architectures and materials science.3DPI: What technical challenges have you encountered so far, and how did you overcome them?Kai Narita: Achieving 10-micron precision for complex cooling needs was challenging. We developed proprietary gel-based metal 3D printing technology, enabling custom designs with 10-micron features with affordable LCD/DLP 3D printers. This breakthrough allows rapid, cost-effective prototyping and production.3DA copper lattice sheet for cooling. Photo via 3D Architech.3DPI: Who do you consider to be the competition in this market? How does your proposition meet underserved needs or outperform?Kai Narita: Our competition includes cold plate manufacturers and micro-additive technologies for data center cooling, and filter makers in the electrolyzer component market for hydrogen production. With 10-micron resolution and micro-architected design, we deliver unmatched precision and efficiency in both sectors.3DPI: What milestones have you achieved, and what are your next major goals?Kai Narita: We completed our pilot productions, validated device performance, and secured PoC requests from top companies. Our next goals are to expand production and scale distribution. We are building partnerships with chemical companies and metal producers and are open to partnerships with lithography-based 3D printing companies (e.g., LCD, SLA, DLP).3DPI: Is there anything else you would like to add?Kai Narita: We are based in Boston, USA, and Sendai, Japan, both prominent hubs for additive manufacturing and metallurgy, bridging academia and industry to enhance innovation and collaboration.Read more about nominees for the 2024 3D Printing Industry Start-up of the Year, including FIDENTIS and Hyphen Innovations, and dont forget to vote.Subscribe to the3D Printing Industry newsletterto keep up with the latest 3D printing news.You can also follow us onTwitter, like ourFacebookpage, and subscribe to the3D Printing Industry Youtubechannel to access more exclusive content.Featured image shows 3DA micro-architected nickel lattice for water electrolyzer. Photo via 3D Architech.