Multimaterial 3D Printing Enables High-Performance Thick-Panel Origami Structures

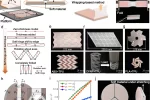

Researchers from the Southern University of Science and Technology (SUSTech) in Shenzhen and City University of Hong Kong have unveiled a manufacturing strategy for thick-panel origami structures that promises unprecedented load-bearing capabilities and flexibility. Published in Nature Communications, their approach uses a single fused deposition modeling (FDM) multimaterial 3D printer to create rigid panels fully wrapped in soft, stretchable hinges. This design allows each origami unit to hold more than 11,000 times its own weight, withstand over 100 cycles of 40% compressive strain, and absorb substantial impact forces.Origame metamaterials. Image via Nature Communications.The research team employed the Ultimaker S5, produced by Netherlands-based Ultimaker, to print polylactic acid (PLA) cores entirely encased in thermoplastic polyurethane (TPU). Conventional attempts at thick-panel origami often fail at the interface between stiff and flexible components, leading to delamination or limited foldability. By contrast, wrapping PLA panels in continuous layers of TPU produces robust hinges that handle large tension during folding without debonding. This wrapping approach eliminates complex assembly processeslike manually adhering thick panels or rolling hingesand ensures reliable performance under cyclic loading.The Ultimaker S5 Pro Bundle complete with Air Manager and Material Station. Photo via UltimakerSelf-Locking Origami for Structural StrengthTwo 3D printed thick-panel Miura-origami sheets can be stacked to form a self-locking unit. A key innovation is the push-to-pull (P2P) deformation mode, which channels vertical compression into the horizontal stretch of soft hinges. During tests, four self-locking units collectively supported more than 260 kilograms and exhibited full recovery after repeated loading. This ability to sustain large compressive strains without permanent deformation results from transferring loads through flexible hinges rather than risking panel buckling.Finite element analysis (FEA) simulations and a custom theoretical model helped pinpoint the geometric parameters required to avoid buckling and maintain the P2P mode. Adjusting factors such as hinge length, wall thickness, and the angles between panels enables programmable mechanical responses. When configured properly, the origami supports static loads and resists cyclic stresses. In addition, stacking multiple origami layers significantly lowers impact forces. One three-layer setup reduced peak impact by 72.1% under a 72J drop test, underscoring its potential in protective applications.Fabrication and design of thick-panel origami. Image via Nature Communications.From Prototypes to Real-World ApplicationsBecause the fabrication process directly prints rigid and soft parts in one piece, origami designs can be customized to suit specific engineering needs. Potential applications include energy-absorbing panels for helmets, deployment mechanisms in aerospace, and flexible supports for robotics. The research team also envisions experimenting with other materials, such as carbon-fiber-reinforced polymers, to increase stiffness or tune energy absorption.Origami Structure Stress Test. Image via Nature Communications.The thick-panel origami method addresses longstanding obstaclesparticularly in managing thickness while preserving flexible foldingto bring origami-inspired metamaterials closer to mainstream use. By combining simple 3D printing workflows with a well-defined geometric model, researchers have demonstrated how these foldable structures can exceed typical load-bearing expectations.This work was supported by Chinas National Key Research and Development Program (2020YFB1312900), the National Natural Science Foundation (11922215), and additional grants from the Science Technology and Innovation Commission of Shenzhen Municipality, the Natural Science Foundation of Guangdong Province, and City University of Hong Kong. Design and mechanical performance of self-locking thick-panel origami. Image via Nature Communications.Ready to discover who won the 20243D Printing Industry Awards?What will the future of 3D printing look like?Which recent trends are driving the 3D printing industry, as highlighted by experts?Subscribe to the 3D Printing Industry newsletter to stay updated with the latest news and insights.Stay connected with the latest in 3D printing by following us on Twitter and Facebook, and dont forget to subscribe to the 3D Printing Industry YouTube channel for more exclusive content.Feature image shows Fabrication and design of thick-panel origami. Image via Nature Communications.