Open-source 3D Printed Pipe Fittings Reduce Water Waste, New Study Argues

3dprintingindustry.com

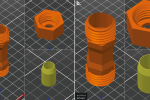

Researchers from Canadas Western University have developed a new open-source approach for 3D printing water pipe fittings.According to the London, Ontario-based team, around 126 billion cubic meters of water are lost globally each year, mainly due to leakage and broken pipes. The researchers believe using a parametric-driven method for local, on-demand 3D printing of customized fittings will unlock more efficient water management.Their easy-connect design offers compatibility with various dimensions and materials used in most pipes on the market. During testing, the couplings withstood up to 4.551 MPa, eight times the standard residential water pressure. They were also found to be 3 to 17 times cheaper than their commercial counterparts, reportedly offering an affordable and sustainable solution to manage water repairs.Co-authored by open-source advocate Dr. Joshua Pearce, the paper was published in the Journal of Manufacturing and Materials Processing. It argues that localized, 3D printing offers value for residential, agricultural, and renewable energy sectors. They also argue that this distributed manufacturing approach is ideal for those in developing regions and remote locations facing equipment shortages.The 3D models have been uploaded to Open Science Framework (OSF) and GitHub, allowing them to be downloaded, modified, and 3D printed by anyone for free. Released under the GNU General Public License 3.0 (GPL 3.0), the files can be accessed, edited, and shared without restrictions.20 mm diameter PETG 3D printed pipe fitting parts. Photos via the Journal of Manufacturing and Materials Processing.Enhancing water security with 3D printing In their study, the Western University researchers highlighted that the worlds growing population and climate change-related water shortages have increased the demand for drinking water. This is compounded by leaks, which cause 346 million cubic meters of lost water around the world every day.The authors note that the piping in many developing countries is old and degraded due to corrosion and environmental conditions. The high cost of standard piping equipment and fittings means old components often go unreplaced, while minor leaks are regularly neglected. This contributes to wasted resources and inflated pumping costs to compensate for reduced pressure.Despite global sustainability efforts, around 30% of the worlds population remains without access to readily treated drinking water. Additionally, according to the researchers, approximately half of humanity faces water scarcity for at least one month every year. Indeed, over 2 million people in the US, Canada, and Australia face limited water access due to poor plumbing and inadequate wastewater disposal.Based at Western Universitys Mechanical and Materials Engineering and Electrical and Computer Engineering departments, the research team believes their approach offers an affordable, sustainable, and accessible solution to this problem. They argue that an open-source parametric design for customized 3D printed pipe fittings would be economically feasible and simple, allowing those with minimal experience to fix leaking pipes at the point of need.Open-source, 3D printed water pipe fittingsTo demonstrate their thesis, the researchers first created a script with adjustable design parameters on the open-source CAD software OpenSCAD. Amendable parameters include pipe diameter, thread type, wall thickness, gasket thickness and length, and tolerances. The OpenSCAD script, freely available on OSF and GitHub, can automatically generate a 3D model based on selected input values. This can then be exported as an STL file and sliced, ready for 3D printing.Next, the team 3D printed 12 pipe-fitting and nut samples in two batches. The first included three 10 mm diameter samples each using PLA, PETG, and ASA filament from Chinese materials company Polymaker. The second batch saw three additional fittings 3D printed using PETG for a 20 mm pipe diameter. Flexible TPE filament was used to fabricate the gasket sealing components.All parts were fabricated using Prusa XL and Prusa i3 MK3S desktop FFF 3D printers from Czech OEM Prusa Research. The i3 MK3S was used for the TPE gaskets, while the XL fabricated all other fitting components. 100% infill was leveraged to ensure all components were watertight, while extrusion flow was increased by 5-15% to prevent layer gaps. Support-free 3D printing was also used to minimize material usage, reduce plastic waste, and lower post-processing times.Once printed and assembled, the pipe-fitting components were subjected to hydrostatic pressure testing using a VEVOR hydraulic pressure pump. Each batch underwent at least 16 pressure tests to ensure the reliability and reusability of the 3D printed parts.STL files of the customized pipe fittings for 10 mm (a) and 20 mm (b) diameters. Images via the Journal of Manufacturing and Materials Processing.Ultimately, PETG was the best-performing material, tolerating up to 4.551 0.138 MPa of water pressure. This was followed by ASA and PLA with 2.758 and 2.275 MPa, respectively. The second batch of 20 mm-diameter PETG parts achieved 2.392 0.138 MPa pressure under 17.5 Nm of torque. All results comfortably exceeded residential plumbing requirements of 0.552 MPa.After calculating the 3D printing material, electricity, and manufacturing time prices, the academics found that PLA, ASA, and PETG 10 mm parts cost $1.03, $1.15, and $1.04, respectively. The larger 20 mm PETG fitting came to $3.30 per unit. These are significantly more affordable than a selection of conventionally manufactured counterparts available at RONA, Home Depot, Kent Building Supplies, and Amazon.Ca. The commercial parts highlighted in this research paper reportedly cost between $4.79$18.44 and possess pressure ratings below 1.586 MPa.Practical application of the couplings by connecting two plastic pipes of different materials to a waterjet cutter as a water inlet line. Photo via the Journal of Manufacturing and Materials Processing.3D printing enhances water securityThis is not the first time researchers have leveraged 3D printing to improve access to clean water. Last year, researchers from the University of Bath developed 3D printed lattice structures capable of removing forever chemicals from water sources.According to the team, their ceramic-infused monoliths can remove up to 75% of perfluorooctanoic acid (PFOA) in under three hours. PFOA is one of the most common perfluoroalkyl and polyfluoroalkyl substances (PFAS). Toxic to humans, these man-made chemicals can take up to 1,000 years to break down naturally.Found in many domestic products like non-stick pans, raincoats, paints, fabrics, and firefighting foams, PFAS have been linked to decreased fertility, hormonal changes, liver damage, cardiovascular problems, diabetes, and cancer. The paper, published in The Chemical Engineering Journal, called the findings a significant step in finding an efficient solution to combat chemical contamination.Elsewhere, Singaporean sustainability firm Nano Sun introduced 3D printing water-filtering membranes in 2018 to combat water pollution. A spin-off from Nanyang Technological University (NTU), the company claims its devices are five times more efficient than traditional processes. At its Tuas-based manufacturing plant, Nano Sun can reportedly 3D print 600 sq m of membranes every day. Early adopters included two large multinational semiconductor manufacturers in Singapore and a wastewater plant in China.More recently, ceramic 3D printers and materials manufacturer Lithoz showcased 3D printed water filter membranes developed by Evove at Formnext 2024. Optimized for lithium extraction and industrial water recycling, the membranes are produced using Lithozs CeraFab S320 system. This approach unlocks a fivefold output increase, reduces energy consumption by 80%, and recycles 80% more water.Who won the 2024 3D Printing Industry Awards?Subscribe to the 3D Printing Industry newsletter to keep up with the latest 3D printing news.You can also follow us on LinkedIn, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.Featured image shows STL files of the customized pipe fittings for 10 mm (a) and 20 mm (b) diameters. Images via the Journal of Manufacturing and Materials Processing.

0 Comments

·0 Shares

·42 Views