How 3D printing is personalizing health care

New print jobs

How 3D printing is personalizing health care

Prosthetics are becoming increasing affordable and accessible thanks to 3D printers.

Anne Schmitz and Daniel Freedman, The Conversation

–

May 20, 2025 5:43 pm

|

20

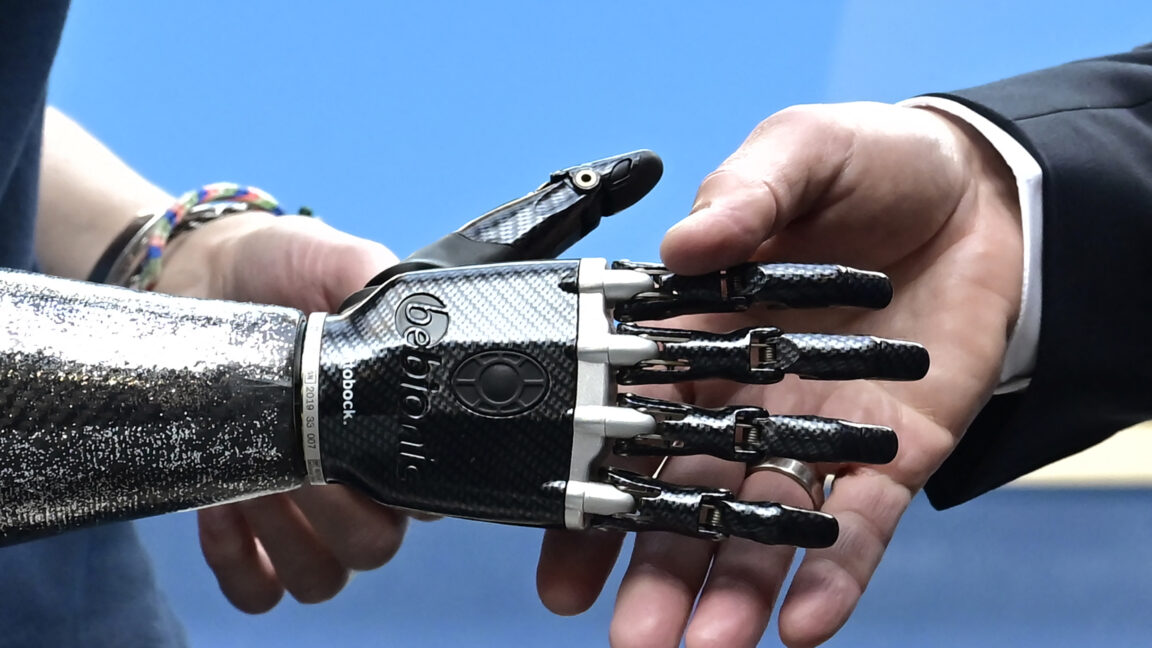

German Chancellor Olaf Scholz shakes hands with the prosthetic hand of a worker of the German med-tech company Ottobock.

Credit:

JOHN MACDOUGALL/AFP via Getty Images

German Chancellor Olaf Scholz shakes hands with the prosthetic hand of a worker of the German med-tech company Ottobock.

Credit:

JOHN MACDOUGALL/AFP via Getty Images

Story text

Size

Small

Standard

Large

Width

*

Standard

Wide

Links

Standard

Orange

* Subscribers only

Learn more

Three-dimensional printing is transforming medical care, letting the health care field shift from mass-produced solutions to customized treatments tailored to each patient’s needs. For instance, researchers are developing 3D-printed prosthetic hands specifically designed for children, made with lightweight materials and adaptable control systems.

These continuing advancements in 3D-printed prosthetics demonstrate their increasing affordability and accessibility. Success stories like this one in personalized prosthetics highlight the benefits of 3D printing, in which a model of an object produced with computer-aided design software is transferred to a 3D printer and constructed layer by layer.

We are a biomedical engineer and a chemist who work with 3D printing. We study how this rapidly evolving technology provides new options not just for prosthetics but for implants, surgical planning, drug manufacturing, and other health care needs. The ability of 3D printing to make precisely shaped objects in a wide range of materials has led to, for example, custom replacement joints and custom-dosage, multidrug pills.

Better body parts

Three-dimensional printing in health care started in the 1980s with scientists using technologies such as stereolithography to create prototypes layer by layer. Stereolithography uses a computer-controlled laser beam to solidify a liquid material into specific 3D shapes. The medical field quickly saw the potential of this technology to create implants and prosthetics designed specifically for each patient.

One of the first applications was creating tissue scaffolds, which are structures that support cell growth. Researchers at Boston Children’s Hospital combined these scaffolds with patients’ own cells to build replacement bladders. The patients remained healthy for years after receiving their implants, demonstrating that 3D-printed structures could become durable body parts.

As technology progressed, the focus shifted to bioprinting, which uses living cells to create working anatomical structures. In 2013, Organovo created the world’s first 3D-bioprinted liver tissue, opening up exciting possibilities for creating organs and tissues for transplantation. But while significant advances have been made in bioprinting, creating full, functional organs such as livers for transplantation remains experimental. Current research focuses on developing smaller, simpler tissues and refining bioprinting techniques to improve cell viability and functionality. These efforts aim to bridge the gap between laboratory success and clinical application, with the ultimate goal of providing viable organ replacements for patients in need.

Three-dimensional printing already has revolutionized the creation of prosthetics. It allows prosthetics makers to produce affordable custom-made devices that fit the patient perfectly. They can tailor prosthetic hands and limbs to each individual and easily replace them as a child grows.

Three-dimensionally printed implants, such as hip replacements and spine implants, offer a more precise fit, which can improve how well they integrate with the body. Traditional implants often come only in standard shapes and sizes.

Some patients have received custom titanium facial implants after accidents. Others had portions of their skulls replaced with 3D-printed implants.

Additionally, 3D printing is making significant strides in dentistry. Companies such as Invisalign use 3D printing to create custom-fit aligners for teeth straightening, demonstrating the ability to personalize dental care.

Scientists are also exploring new materials for 3D printing, such as self-healing bioglass that might replace damaged cartilage. Moreover, researchers are developing 4D printing, which creates objects that can change shape over time, potentially leading to medical devices that can adapt to the body’s needs.

For example, researchers are working on 3D-printed stents that can respond to changes in blood flow. These stents are designed to expand or contract as needed, reducing the risk of blockage and improving long-term patient outcomes.

Simulating surgeries

Three-dimensionally printed anatomical models often help surgeons understand complex cases and improve surgical outcomes. These models, created from medical images such as X-rays and CT scans, allow surgeons to practice procedures before operating.

For instance, a 3D-printed model of a child’s heart enables surgeons to simulate complex surgeries. This approach can lead to shorter operating times, fewer complications, and lower costs.

Personalized pharmaceuticals

In the pharmaceutical industry, drugmakers can three-dimensionally print personalized drug dosages and delivery systems. The ability to precisely layer each component of a drug means that they can make medicines with the exact dose needed for each patient. The 3D-printed anti-epileptic drug Spritam was approved by the Food and Drug Administration in 2015 to deliver very high dosages of its active ingredient.

Drug production systems that use 3D printing are finding homes outside pharmaceutical factories. The drugs potentially can be made and delivered by community pharmacies. Hospitals are starting to use 3D printing to make medicine on-site, allowing for personalized treatment plans based on factors such as the patient’s age and health.

However, it’s important to note that regulations for 3D-printed drugs are still being developed. One concern is that postprinting processing may affect the stability of drug ingredients. It’s also important to establish clear guidelines and decide where 3D printing should take place – whether in pharmacies, hospitals or even at home. Additionally, pharmacists will need rigorous training in these new systems.

Printing for the future

Despite the extraordinarily rapid progress overall in 3D printing for health care, major challenges and opportunities remain. Among them is the need to develop better ways to ensure the quality and safety of 3D-printed medical products. Affordability and accessibility also remain significant concerns. Long-term safety concerns regarding implant materials, such as potential biocompatibility issues and the release of nanoparticles, require rigorous testing and validation.

While 3D printing has the potential to reduce manufacturing costs, the initial investment in equipment and materials can be a barrier for many health care providers and patients, especially in underserved communities. Furthermore, the lack of standardized workflows and trained personnel can limit the widespread adoption of 3D printing in clinical settings, hindering access for those who could benefit most.

On the bright side, artificial intelligence techniques that can effectively leverage vast amounts of highly detailed medical data are likely to prove critical in developing improved 3D-printed medical products. Specifically, AI algorithms can analyze patient-specific data to optimize the design and fabrication of 3D-printed implants and prosthetics. For instance, implant makers can use AI-driven image analysis to create highly accurate 3D models from CT scans and MRIs that they can use to design customized implants.

Furthermore, machine learning algorithms can predict the long-term performance and potential failure points of 3D-printed prosthetics, allowing prosthetics designers to optimize for improved durability and patient safety.

Three-dimensional printing continues to break boundaries, including the boundary of the body itself. Researchers at the California Institute of Technology have developed a technique that uses ultrasound to turn a liquid injected into the body into a gel in 3D shapes. The method could be used one day for delivering drugs or replacing tissue.

Overall, the field is moving quickly toward personalized treatment plans that are closely adapted to each patient’s unique needs and preferences, made possible by the precision and flexibility of 3D printing.

Anne Schmitz, Associate Professor of Engineering, University of Wisconsin-Stout and Daniel Freedman, Dean of the College of Science, Technology, Engineering, Mathematics & Management, University of Wisconsin-Stout. This article is republished from The Conversation under a Creative Commons license. Read the original article.

Anne Schmitz and Daniel Freedman, The Conversation

The Conversation is an independent source of news and views, sourced from the academic and research community. Our team of editors work with these experts to share their knowledge with the wider public. Our aim is to allow for better understanding of current affairs and complex issues, and hopefully improve the quality of public discourse on them.

20 Comments

#how #printing #personalizing #healthcareHow 3D printing is personalizing health care

New print jobs

How 3D printing is personalizing health care

Prosthetics are becoming increasing affordable and accessible thanks to 3D printers.

Anne Schmitz and Daniel Freedman, The Conversation

–

May 20, 2025 5:43 pm

|

20

German Chancellor Olaf Scholz shakes hands with the prosthetic hand of a worker of the German med-tech company Ottobock.

Credit:

JOHN MACDOUGALL/AFP via Getty Images

German Chancellor Olaf Scholz shakes hands with the prosthetic hand of a worker of the German med-tech company Ottobock.

Credit:

JOHN MACDOUGALL/AFP via Getty Images

Story text

Size

Small

Standard

Large

Width

*

Standard

Wide

Links

Standard

Orange

* Subscribers only

Learn more

Three-dimensional printing is transforming medical care, letting the health care field shift from mass-produced solutions to customized treatments tailored to each patient’s needs. For instance, researchers are developing 3D-printed prosthetic hands specifically designed for children, made with lightweight materials and adaptable control systems.

These continuing advancements in 3D-printed prosthetics demonstrate their increasing affordability and accessibility. Success stories like this one in personalized prosthetics highlight the benefits of 3D printing, in which a model of an object produced with computer-aided design software is transferred to a 3D printer and constructed layer by layer.

We are a biomedical engineer and a chemist who work with 3D printing. We study how this rapidly evolving technology provides new options not just for prosthetics but for implants, surgical planning, drug manufacturing, and other health care needs. The ability of 3D printing to make precisely shaped objects in a wide range of materials has led to, for example, custom replacement joints and custom-dosage, multidrug pills.

Better body parts

Three-dimensional printing in health care started in the 1980s with scientists using technologies such as stereolithography to create prototypes layer by layer. Stereolithography uses a computer-controlled laser beam to solidify a liquid material into specific 3D shapes. The medical field quickly saw the potential of this technology to create implants and prosthetics designed specifically for each patient.

One of the first applications was creating tissue scaffolds, which are structures that support cell growth. Researchers at Boston Children’s Hospital combined these scaffolds with patients’ own cells to build replacement bladders. The patients remained healthy for years after receiving their implants, demonstrating that 3D-printed structures could become durable body parts.

As technology progressed, the focus shifted to bioprinting, which uses living cells to create working anatomical structures. In 2013, Organovo created the world’s first 3D-bioprinted liver tissue, opening up exciting possibilities for creating organs and tissues for transplantation. But while significant advances have been made in bioprinting, creating full, functional organs such as livers for transplantation remains experimental. Current research focuses on developing smaller, simpler tissues and refining bioprinting techniques to improve cell viability and functionality. These efforts aim to bridge the gap between laboratory success and clinical application, with the ultimate goal of providing viable organ replacements for patients in need.

Three-dimensional printing already has revolutionized the creation of prosthetics. It allows prosthetics makers to produce affordable custom-made devices that fit the patient perfectly. They can tailor prosthetic hands and limbs to each individual and easily replace them as a child grows.

Three-dimensionally printed implants, such as hip replacements and spine implants, offer a more precise fit, which can improve how well they integrate with the body. Traditional implants often come only in standard shapes and sizes.

Some patients have received custom titanium facial implants after accidents. Others had portions of their skulls replaced with 3D-printed implants.

Additionally, 3D printing is making significant strides in dentistry. Companies such as Invisalign use 3D printing to create custom-fit aligners for teeth straightening, demonstrating the ability to personalize dental care.

Scientists are also exploring new materials for 3D printing, such as self-healing bioglass that might replace damaged cartilage. Moreover, researchers are developing 4D printing, which creates objects that can change shape over time, potentially leading to medical devices that can adapt to the body’s needs.

For example, researchers are working on 3D-printed stents that can respond to changes in blood flow. These stents are designed to expand or contract as needed, reducing the risk of blockage and improving long-term patient outcomes.

Simulating surgeries

Three-dimensionally printed anatomical models often help surgeons understand complex cases and improve surgical outcomes. These models, created from medical images such as X-rays and CT scans, allow surgeons to practice procedures before operating.

For instance, a 3D-printed model of a child’s heart enables surgeons to simulate complex surgeries. This approach can lead to shorter operating times, fewer complications, and lower costs.

Personalized pharmaceuticals

In the pharmaceutical industry, drugmakers can three-dimensionally print personalized drug dosages and delivery systems. The ability to precisely layer each component of a drug means that they can make medicines with the exact dose needed for each patient. The 3D-printed anti-epileptic drug Spritam was approved by the Food and Drug Administration in 2015 to deliver very high dosages of its active ingredient.

Drug production systems that use 3D printing are finding homes outside pharmaceutical factories. The drugs potentially can be made and delivered by community pharmacies. Hospitals are starting to use 3D printing to make medicine on-site, allowing for personalized treatment plans based on factors such as the patient’s age and health.

However, it’s important to note that regulations for 3D-printed drugs are still being developed. One concern is that postprinting processing may affect the stability of drug ingredients. It’s also important to establish clear guidelines and decide where 3D printing should take place – whether in pharmacies, hospitals or even at home. Additionally, pharmacists will need rigorous training in these new systems.

Printing for the future

Despite the extraordinarily rapid progress overall in 3D printing for health care, major challenges and opportunities remain. Among them is the need to develop better ways to ensure the quality and safety of 3D-printed medical products. Affordability and accessibility also remain significant concerns. Long-term safety concerns regarding implant materials, such as potential biocompatibility issues and the release of nanoparticles, require rigorous testing and validation.

While 3D printing has the potential to reduce manufacturing costs, the initial investment in equipment and materials can be a barrier for many health care providers and patients, especially in underserved communities. Furthermore, the lack of standardized workflows and trained personnel can limit the widespread adoption of 3D printing in clinical settings, hindering access for those who could benefit most.

On the bright side, artificial intelligence techniques that can effectively leverage vast amounts of highly detailed medical data are likely to prove critical in developing improved 3D-printed medical products. Specifically, AI algorithms can analyze patient-specific data to optimize the design and fabrication of 3D-printed implants and prosthetics. For instance, implant makers can use AI-driven image analysis to create highly accurate 3D models from CT scans and MRIs that they can use to design customized implants.

Furthermore, machine learning algorithms can predict the long-term performance and potential failure points of 3D-printed prosthetics, allowing prosthetics designers to optimize for improved durability and patient safety.

Three-dimensional printing continues to break boundaries, including the boundary of the body itself. Researchers at the California Institute of Technology have developed a technique that uses ultrasound to turn a liquid injected into the body into a gel in 3D shapes. The method could be used one day for delivering drugs or replacing tissue.

Overall, the field is moving quickly toward personalized treatment plans that are closely adapted to each patient’s unique needs and preferences, made possible by the precision and flexibility of 3D printing.

Anne Schmitz, Associate Professor of Engineering, University of Wisconsin-Stout and Daniel Freedman, Dean of the College of Science, Technology, Engineering, Mathematics & Management, University of Wisconsin-Stout. This article is republished from The Conversation under a Creative Commons license. Read the original article.

Anne Schmitz and Daniel Freedman, The Conversation

The Conversation is an independent source of news and views, sourced from the academic and research community. Our team of editors work with these experts to share their knowledge with the wider public. Our aim is to allow for better understanding of current affairs and complex issues, and hopefully improve the quality of public discourse on them.

20 Comments

#how #printing #personalizing #healthcare