0 Commentaires

0 Parts

17 Vue

Annuaire

Annuaire

-

Connectez-vous pour aimer, partager et commenter!

-

WWW.CHAOS.COMSubsurface scattering explainedChallenges and optimization strategies It’s important to remember that SSS may appear a bit off due to issues such as overlapping faces, solid objects that are not closed (holes, unwelded vertices), lack of thickness, and incorrect scaling. To prevent this from happening, try not to rush when working on a project. Ensure your geometry is clean by taking regular breaks, being observant, and fixing any object irregularities you spot. To wrap it up Substance scattering is an excellent tool for adding an extra level of photorealism to your renders. It takes into account the physical properties of light and the way it interacts with each unique object, preventing them from looking plastic-like and creating a realistic representation of the scene’s surroundings. We encourage you to experiment and play around with the different shaders in V-Ray and explore which ones incorporate best into your workflow. FAQs Should I use subsurface scattering? You should definitely use SSS, especially for translucent objects. It can help make a huge difference in creating realistic skin, wax, marble, liquids, foliage, and more. What objects have subsurface scattering? Any semi-translucent material where scattered light diffuses inside — skin, wax, marble and jade, fruits, milk, juice, leaves are just some examples. How can I improve my renders using subsurface scattering? Use SSS for the right materials, and experiment with different shaders to see which one gets it just right. Does enabling subsurface scattering increase render time? Yes, but if used smartly, not by much. You can manage performance by using it selectively, and keeping in mind it’s a trade-off between time and quality. Why is subsurface scattering important for 3D artists? SSS mimics how light interacts with real-world materials through scattering. Without SSS, materials lack depth and look artificial — skin looks plastic, wax looks flat, and characters, close-ups, and product shots lack photorealism.0 Commentaires 0 Parts 23 Vue

WWW.CHAOS.COMSubsurface scattering explainedChallenges and optimization strategies It’s important to remember that SSS may appear a bit off due to issues such as overlapping faces, solid objects that are not closed (holes, unwelded vertices), lack of thickness, and incorrect scaling. To prevent this from happening, try not to rush when working on a project. Ensure your geometry is clean by taking regular breaks, being observant, and fixing any object irregularities you spot. To wrap it up Substance scattering is an excellent tool for adding an extra level of photorealism to your renders. It takes into account the physical properties of light and the way it interacts with each unique object, preventing them from looking plastic-like and creating a realistic representation of the scene’s surroundings. We encourage you to experiment and play around with the different shaders in V-Ray and explore which ones incorporate best into your workflow. FAQs Should I use subsurface scattering? You should definitely use SSS, especially for translucent objects. It can help make a huge difference in creating realistic skin, wax, marble, liquids, foliage, and more. What objects have subsurface scattering? Any semi-translucent material where scattered light diffuses inside — skin, wax, marble and jade, fruits, milk, juice, leaves are just some examples. How can I improve my renders using subsurface scattering? Use SSS for the right materials, and experiment with different shaders to see which one gets it just right. Does enabling subsurface scattering increase render time? Yes, but if used smartly, not by much. You can manage performance by using it selectively, and keeping in mind it’s a trade-off between time and quality. Why is subsurface scattering important for 3D artists? SSS mimics how light interacts with real-world materials through scattering. Without SSS, materials lack depth and look artificial — skin looks plastic, wax looks flat, and characters, close-ups, and product shots lack photorealism.0 Commentaires 0 Parts 23 Vue -

WWW.NINTENDOLIFE.COMMost US amiibo Pre-Orders Have Gone Live, But Someone's Still MissingImage: Nintendo LifeYesterday saw the flood gates open for a whole bunch of Nintendo pre-orders across the US, including a first chance to pick up the new Zelda: Tears of the Kingdom Sage amiibo. We've been excited to get our hands on these initial fab four since they were revealed in the Switch 2 Direct, but, as many discovered yesterday, only three of them showed up to play. Riju, Tulin and Sidon are all present and correct, with pre-orders appearing on the likes of GameStop, Walmart and Best Buy as expected, but our beloved Yunobo is nowhere to be seen. The US pre-order information for the Goron Sage still hasn't appeared online, and we've read that any in-store attempts have been just as fruitless.Subscribe to Nintendo Life on YouTube810kWatch on YouTube Looking around US retailers, the Goron model is still listed as "Coming Soon", while the other three are all available to pick up with their new $29.99 price tag. Image: Nintendo Life Despite this pre-order no-show, the amiibo is still slated for a 5th June release date, and European pre-orders have gone live as planned (at the lower £16.99 price point). Perhaps things will brighten up once the region's My Nintendo Store pre-orders open to invitees on 8th May... maybe. We have reached out to Nintendo for a comment on this situation and will keep you updated should we hear any developments. The final TOTK Sage, Mineru's Construct, will be getting the amiibo treatment at some point down the line, but Nintendo has yet to reveal the finished model or release date. And if that wasn't enough, we also have a trio of new Street Fighter 6 amiibo to look forward to, all of which are available to pre-order in the States as planned. So, time for the big question: Did you manage to place your Yunobo pre-order? You can let us know in the following poll, then take to the comments to share your storefront stories. Did you manage to get the Yunobo amiibo? (108 votes) Yep (in Europe)18%Yep (in the US)2%Nope, but I'm still looking32%Nope, and I've given up hope3%I didn't even bother trying45% A pre-orderly fashion Update: £16.99 on My Nintendo Store in the UK Please note that some external links on this page are affiliate links, which means if you click them and make a purchase we may receive a small percentage of the sale. Please read our FTC Disclosure for more information. Related Games See Also Share:0 0 Jim came to Nintendo Life in 2022 and, despite his insistence that The Minish Cap is the best Zelda game and his unwavering love for the Star Wars prequels (yes, really), he has continued to write news and features on the site ever since. Hold on there, you need to login to post a comment... Related Articles Nintendo Confirms Upgrade Pack Price For More 'Switch 2 Edition' Titles Update: Some US prices also confirmed Where To Pre-Order Nintendo Switch 2 Where to buy Switch 2 consoles, accessories & games Paul Rudd Returns In An Awesome SNES-Style Switch 2 Commercial Super together! Nintendo Removes Worrying Cloud Save Note From Select Switch 2 Game Pages Update: This Cloud had a silver lining Feature: 27 GameCube Games We'd Love To See On Nintendo Switch 2 NSO Born to Play... on Switch 20 Commentaires 0 Parts 22 Vue

WWW.NINTENDOLIFE.COMMost US amiibo Pre-Orders Have Gone Live, But Someone's Still MissingImage: Nintendo LifeYesterday saw the flood gates open for a whole bunch of Nintendo pre-orders across the US, including a first chance to pick up the new Zelda: Tears of the Kingdom Sage amiibo. We've been excited to get our hands on these initial fab four since they were revealed in the Switch 2 Direct, but, as many discovered yesterday, only three of them showed up to play. Riju, Tulin and Sidon are all present and correct, with pre-orders appearing on the likes of GameStop, Walmart and Best Buy as expected, but our beloved Yunobo is nowhere to be seen. The US pre-order information for the Goron Sage still hasn't appeared online, and we've read that any in-store attempts have been just as fruitless.Subscribe to Nintendo Life on YouTube810kWatch on YouTube Looking around US retailers, the Goron model is still listed as "Coming Soon", while the other three are all available to pick up with their new $29.99 price tag. Image: Nintendo Life Despite this pre-order no-show, the amiibo is still slated for a 5th June release date, and European pre-orders have gone live as planned (at the lower £16.99 price point). Perhaps things will brighten up once the region's My Nintendo Store pre-orders open to invitees on 8th May... maybe. We have reached out to Nintendo for a comment on this situation and will keep you updated should we hear any developments. The final TOTK Sage, Mineru's Construct, will be getting the amiibo treatment at some point down the line, but Nintendo has yet to reveal the finished model or release date. And if that wasn't enough, we also have a trio of new Street Fighter 6 amiibo to look forward to, all of which are available to pre-order in the States as planned. So, time for the big question: Did you manage to place your Yunobo pre-order? You can let us know in the following poll, then take to the comments to share your storefront stories. Did you manage to get the Yunobo amiibo? (108 votes) Yep (in Europe)18%Yep (in the US)2%Nope, but I'm still looking32%Nope, and I've given up hope3%I didn't even bother trying45% A pre-orderly fashion Update: £16.99 on My Nintendo Store in the UK Please note that some external links on this page are affiliate links, which means if you click them and make a purchase we may receive a small percentage of the sale. Please read our FTC Disclosure for more information. Related Games See Also Share:0 0 Jim came to Nintendo Life in 2022 and, despite his insistence that The Minish Cap is the best Zelda game and his unwavering love for the Star Wars prequels (yes, really), he has continued to write news and features on the site ever since. Hold on there, you need to login to post a comment... Related Articles Nintendo Confirms Upgrade Pack Price For More 'Switch 2 Edition' Titles Update: Some US prices also confirmed Where To Pre-Order Nintendo Switch 2 Where to buy Switch 2 consoles, accessories & games Paul Rudd Returns In An Awesome SNES-Style Switch 2 Commercial Super together! Nintendo Removes Worrying Cloud Save Note From Select Switch 2 Game Pages Update: This Cloud had a silver lining Feature: 27 GameCube Games We'd Love To See On Nintendo Switch 2 NSO Born to Play... on Switch 20 Commentaires 0 Parts 22 Vue -

TECHCRUNCH.COMData breach at Connecticut’s Yale New Haven Health affects over 5 millionIn Brief Posted: 6:00 AM PDT · April 25, 2025 Image Credits:Tim Clayton / Corbis / Getty Images Data breach at Connecticut’s Yale New Haven Health affects over 5 million A data breach at Connecticut’s largest healthcare system Yale New Haven Health affects more than 5.5 million people, according to a legally required notice with the U.S. government’s health department. Yale New Haven said the March cyberattack allowed malicious hackers to obtain copies of patients’ personally identifiable information and some healthcare-related data. Per a notice on the healthcare system’s website, the stolen data varies by person, but can include patient names, dates of birth, postal and email addresses, phone number, race and ethnicity data, and Social Security numbers. The stolen data also includes information about types of patients and medical record numbers. Local media quoted the healthcare system’s spokesperson as saying that the number of affected individuals “may change.” A spokesperson for Yale New Haven did not immediately comment when contacted by TechCrunch. This is the second major healthcare data breach confirmed this week, after Blue Shield of California revealed it shared health data of 4.7 million patients with Google over several years. Topics0 Commentaires 0 Parts 33 Vue

TECHCRUNCH.COMData breach at Connecticut’s Yale New Haven Health affects over 5 millionIn Brief Posted: 6:00 AM PDT · April 25, 2025 Image Credits:Tim Clayton / Corbis / Getty Images Data breach at Connecticut’s Yale New Haven Health affects over 5 million A data breach at Connecticut’s largest healthcare system Yale New Haven Health affects more than 5.5 million people, according to a legally required notice with the U.S. government’s health department. Yale New Haven said the March cyberattack allowed malicious hackers to obtain copies of patients’ personally identifiable information and some healthcare-related data. Per a notice on the healthcare system’s website, the stolen data varies by person, but can include patient names, dates of birth, postal and email addresses, phone number, race and ethnicity data, and Social Security numbers. The stolen data also includes information about types of patients and medical record numbers. Local media quoted the healthcare system’s spokesperson as saying that the number of affected individuals “may change.” A spokesperson for Yale New Haven did not immediately comment when contacted by TechCrunch. This is the second major healthcare data breach confirmed this week, after Blue Shield of California revealed it shared health data of 4.7 million patients with Google over several years. Topics0 Commentaires 0 Parts 33 Vue -

WWW.ARTOFVFX.COMDoctor Who – Lux: Behind the Scenes by BBCFrom concept to final pixel — go inside Doctor Who: Lux with the BBC‘s behind-the-scenes feature and see how Framestore’s artists crafted the episode’s dazzling VFX and animation! © Vincent Frei – The Art of VFX – 2025 The post Doctor Who – Lux: Behind the Scenes by BBC appeared first on The Art of VFX.0 Commentaires 0 Parts 20 Vue

WWW.ARTOFVFX.COMDoctor Who – Lux: Behind the Scenes by BBCFrom concept to final pixel — go inside Doctor Who: Lux with the BBC‘s behind-the-scenes feature and see how Framestore’s artists crafted the episode’s dazzling VFX and animation! © Vincent Frei – The Art of VFX – 2025 The post Doctor Who – Lux: Behind the Scenes by BBC appeared first on The Art of VFX.0 Commentaires 0 Parts 20 Vue -

3DPRINTINGINDUSTRY.COMRAPID + TCT 2025 3D Printing for Defense: New Insights from the U.S. Army, BlueForge Alliance, Boeing, and MoreAerospace and defense now rank among the largest and most valuable sectors adopting additive manufacturing. Ongoing international supply chain disruptions, rising geopolitical tensions, and global conflicts threaten access to critical equipment and components vital for national security. In response, defense agencies are turning to 3D printing to cut lead times, localize production, repair equipment, and restock depleted inventories. This growing focus on 3D printing for defense was evident at RAPID + TCT 2025, which co-located with the eighth edition of SME’s AeroDef Manufacturing 2025 expo. A large section of the show floor at Detroit’s Huntington Place was dedicated to key exhibitors within the military technology ecosystem. This included heat exchanger manufacturer Conflux Technology, aerospace 3D printing firm Hyphen Innovations, and US defense manufacturing accelerator LIFT. Read more RAPID + TCT 2025 news and executive insights AeroDef also featured a stacked conference track. Expert-led presentations and panels provided insights into the value, opportunities, and challenges facing the defense industrial base. Major General Michael Lalor of the U.S. Army highlighted 3D printing’s role in sustaining 70% of the infantry’s combat inventory. He also emphasized its importance for building an “arsenal of democracy” in Detroit. RHH Advisory’s Tali Rosman identified 3D printing’s potential to increase the pace of American manufacturing. This is particularly significant given that China’s shipbuilding capacity is currently 350 times greater than that of the United States. A BlueForge Alliance-led panel discussed how to accelerate production in the U.S. Navy’s industrial base, highlighting the value and challenges surrounding 3D printing adoption. Elsewhere, Dr. Bill Anderson highlighted the cybersecurity threats that malicious foreign actors pose to the digital ecosystem of additive manufacturing. Boeing’s Daniel Braley was also on the agenda. He highlighted vulnerabilities in the supply chain for critical minerals and materials, citing the “threat of the U.S. going to full-scale war in one to two years.” As geopolitical tensions rise and global supply chains constrict, all speakers broadly agreed that 3D printing will become a critical strategic pillar in safeguarding the West’s defense industrial base. The AeroDef Manufacturing 2025 expo show floor. Photo by 3D Printing Industry. Major General Michael Lalor: Advanced manufacturing at U.S. Army TACOM Major General Michael B. Lalor, Commanding General of U.S. Army Tank-automotive and Armaments Command (TACOM), opened the AeroDef conference with a welcome address. Headquartered at Detroit Arsenal, the Command manages 70% of the U.S. Army’s ground combat inventory. “If a soldier drives it, shoots it, or wears it, we sustain it,” Lalor explained. TACOM oversees a $30 billion annual budget and manages over 3,500 weapon systems. According to the former M1A1 Tank Platoon Leader, these include everything from Abrams and Bradley tanks to eight-wheeled Stryker armored fighting vehicles and artillery systems. TACOM maintains a global presence. At any given time, about 350 personnel across 70 “flyaway teams” operate overseas, supporting supply chain operations for units in the field. Collaboration with industry partners is vital for TACOM’s operations. He noted that technological evolution and supply chain complexities demand new levels of collaboration that transcend “international and traditional boundaries.” Lalor added that TACOM is leading the U.S. Army in advanced manufacturing. 3D printing is being leveraged to fabricate customized parts on demand, reducing reliance on lengthy lead times. TACOM’s Major General highlighted that the Command has seen “amazing results” through this adoption. Over the past year, TACOM has developed its Battle Damage Repair and Fabrication Program (BDRF). The initiative leverages additive manufacturing to produce temporary replacement parts for damaged military vehicles. This reduces downtime and increases operational readiness, allowing critical warfighting equipment to be returned to the battlefield in less time. Over 40,000 vehicle parts have been assessed for additive manufacturability in collaboration with the U.S. Army DEVCOM Ground Vehicle Systems Center and TACOM Integrated Logistics Support Center. From this, TACOM’s Rock Island Arsenal – Joint Manufacturing and Technology Center in Illinois has 3D printed more than 600 3D CAD models. According to Lalor, these efforts are vital to relieving the substantial pressure on America’s few remaining foundries. The U.S. Army’s only operational foundry at Rock Island has seen its workload quadruple over the past 18 months amid a dearth of domestic castings and forgings capabilities. Lalor revealed that Rock Hill Arsenal’s additive manufacturing technologies will be ASTM 9100 compliant by June 2025, when it will ramp up production of aerospace and aviation-certified parts. “There are gaps to close, and that arsenal is part of the solution,” he added. Major General Michael Lalor speaking at AeroDef Manufacturing 2025. Photo by 3D Printing Industry. The value of 3D printing for defense In a separate presentation, Tali Rosman, a Business and M&A advisor at RHH Advisory and former Elem Additive CEO, shared her perspective on the defense opportunity for 3D printing. Rosman emphasized the U.S. Department of Defense’s (DOD) growing adoption of additive manufacturing, suggesting that the Pentagon is “arguably the largest user” of additive manufacturing based on dollars spent. However, this adoption comes amid a challenging point for the Pentagon. According to Rosman, “China is outpacing the U.S. in terms of manufacturing.” Notably, she highlighted that China’s shipbuilding capacity is 350 times that of the United States. Amid this threat, the DOD is adopting additive manufacturing “in earnest” to secure the U.S. defense supply chain. While it can take years to build conventional manufacturing plants, some 3D printing technologies can start fabricating parts in weeks. In today’s “volatile and uncertain world,” that speed makes the technology especially appealing. Rosman highlighted expeditionary manufacturing as one key application for 3D printing. She emphasized that conflict in Ukraine has “paved the way” for its remote deployment. Ukrainian soldiers are leveraging metal additive manufacturing, including cold spray 3D printers from SPEE3D, to increase equipment uptime and localize critical supply chains. The U.S. Navy has also installed 3D printers on warships to conduct repairs and fabricate replacement parts at the point of need. Last year, SPEE3D’s XSPEE3D and Snowbird Technologies’ SAMM Tech hybrid DED manufacturing system were deployed during the Rim of the Pacific (RIMPAC) exercise in Hawaii. During the trial, Navy personnel sought to reduce the delivery time of critical parts from days to hours. Additionally, Rosman highlighted increased DOD funding to restock its depleted missile arsenals using 3D printing. She pointed to Albuquerque-based aerospace firm X-Bow Launch Systems, which recently received an additional $9.85 million from the DOD to advance research into 3D printed solid rocket motors (SRMs). This new capital sees the company’s current DOD contract value rise to $28.67 million, while its total U.S. defense funding has exceeded $97 million. Similarly, the Pentagon has backed Ursa Major to 3D print missile SRMs. Last December, the Colorado-based firm completed successful flight testing for the U.S. Army. Daniel Jablonsky, Ursa Major’s CEO, claimed that the company’s Lynx 3D printing technology unlocked “unprecedented timelines,” with nearly 300 SRM static test fires completed in 2024. Looking ahead, Rosman anticipates that 3D printing will play an increasing role for many of America’s allies. European countries are expected to ramp up defense funding, following the Trump administration’s call for increased security spending among NATO members. For instance, Germany’s defense spending could grow to 3% of GDP by 2027, potentially exceeding 3.5% after that, according to Goldman Sachs research. Rosman believes a “disproportionate” amount of Europe’s funding will be “flowing into the additive manufacturing sector” in the coming years. Indeed, the UK recently outlined plans to accelerate 3D printing for defense. The Ministry of Defense (MOD) aims to increase investment to incentivise adoption, adapt policies to remove barriers, and increasingly integrate additive manufacturing into the defense supply chain. Snowbird Technologies’ 3D printer at RAPID + TCT 2025. Photo by 3D Printing Industry. Additive manufacturing bolsters the US Navy’s industrial base The role of additive manufacturing in the U.S. submarine industrial base (SIB) is also growing. Leading this effort is BlueForge Alliance (BFA), a nonprofit defense integrator. Headquartered in Bryan, Texas, BFA coordinates manufacturing, recruitment, and technology integration to support the U.S. Navy’s manufacturing supply chain. During a panel discussion, Tim Shinbara, BFA’s Chief Strategy Officer, sat down with James Hockey, Director of metal 3D printing service provider Incodema3D, and Greg Mallon, Chief Strategy Officer of engineering and manufacturing firm GSE Dynamics. Incodema3D and GSE Dynamics are among the roughly 16,000 companies working in America’s ship and submarine manufacturing sector. Mallon identified workforce challenges as stunting the growth of America’s maritime industrial base. He noted that over the past 30 years, the U.S. has shifted from a goods-based economy to one driven by digital and service industries. The result? A shrunken manufacturing workforce, down from 3 million to just over a million workers. “That has left the defense industrial base very atrophied,” Mallon added. Additive manufacturing firms, like Incodema3D, are no less affected. “Our biggest problem is still talent,” agreed Hockey. “We can’t hire people fast enough.” The 27-year 3D printing veteran explained that Incodema3D needs to be growing 25% every year “just to keep up with the scaling we’ve already done.” However, the company, which operates out of Freeville, New York, has only grown 30% since its founding in 2013. BluForge Alliance is working to alleviate these shortfalls through buildsubmarines.com, a website that connects workers with employers in the submarine industrial base. According to Shinbara, the recruitment tool offers a low-cost and effective solution to workforce challenges. “It’s only eight cents for someone to apply, and we found it’s about $700 per person to be hired,” he explained. Buildsubmarines.com sign in Detroit. Photo by 3D Printing Industry. Adoption also remains a core challenge within maritime manufacturing. In particular, Hockey identified the need for customers to embrace design for additive manufacturing (DfAM) and understand where the value lies. He highlighted a common issue with additive manufacturing: the assumption that it’s always the faster solution. Specifically, customers are increasingly requesting low-volume casting for legacy parts. Hockey explained that these applications offer little value unless the design includes novel geometries or features enabled by 3D printing. For Mallon, the roadblocks to adoption go beyond the machinery, citing “a lack of enthusiasm to adopt that new technology.” He highlighted a “resistance to change” among experienced workers, often due to job security concerns or comfort with legacy systems. However, there is stronger enthusiasm for 3D printing among younger workers, who “embrace the technology much faster.” Looking to the future of maritime manufacturing, Mallon believes hope lies in predictable defense programs and automation. “When you look at the Navy’s 30-year shipbuilding plan, each year it changes,” he said. “It’s hard to follow.” Mallon believes increased predictability would allow customers to follow through on programs and prioritize execution. Moreover, GSE Dynamics’ Chief Strategy Officer believes increased automation will improve efficiency and speed. Hockey echoed this sentiment, highlighting his company’s internal push for tighter integration between additive manufacturing and CNC machining. Hockey predicted that streamlined workflows will ease staffing pressures while also elevating the overall skill level of the workforce. Shinbara, surveying the broader context from Washington, D.C., concluded with a hopeful note. “The policy, posture, and funding are starting to align,” he said. “It’s probably one of the few times outside of World War Two” that the U.S. has seen this level of policy and financial momentum. Tim Shinbara, Greg Mallon, and James Hockey (L-R). Photo by 3D Printing Industry. Cybersecurity threats and logistical challenges Security threats and supply chain challenges also jeopardize adoption and growth. Dr. Bill Anderson, Principal Product Manager at Mattermost, underscored major cybersecurity concerns. He pointed to the risks tied to additive manufacturing’s expanding digital footprint. Anderson opened his presentation with a stark warning: “The government is under attack from foreign adversaries.” He emphasized that government suppliers, contract manufacturers, and OEMs face significant risk. The digital security expert observed that even manufacturers far from the front lines are under threat, warning, “You’re being attacked now, you probably just don’t know it.” The University of Waterloo alumnus explained that, in wartime, the West’s adversaries may look to shut down suppliers’ systems. This could have knock-on effects, impacting the military and government’s ability to operate. According to Anderson, about 70% of cyberattacks on the defense industrial base are committed by nation states. He pointed to China as a major threat, particularly Volt Typhoon, reportedly a Chinese state-sponsored hacker group engaged in cyberespionage. In 2023, this advanced persistent threat (APT) breached commercial and Navy networks near Guam. While the U.S. successfully thwarted the intrusion, the attack could have severed communications across the Pacific. Such a capability would carry serious strategic consequences, particularly amid escalating tensions over Taiwan. Security threats also impact the supply of critical materials. Braley, a Technical Fellow at Boeing, described the global supply chain as a “perfect storm.” He explained that intensifying threats from Russia, North Korea, China, and Iran have “severely affected” America’s ability to procure raw materials and manufactured parts. Tightening U.S. and international regulations constrain the flow of materials essential to America’s defense manufacturing. According to Braley, “the real issue for the aerospace industry” lies in recent amendments to the National Defense Authorization Act (NDAA), which introduce new import restrictions. Braley noted that most titanium powder used in metal 3D printing is sourced from China. Under the updated NDAA, the DOD could be barred from procuring Chinese titanium powder starting in June 2026. The legislation will also restrict imports of key steel and metal alloys, including nickel, iron, cobalt, zirconium, and their derivatives. Braley is especially concerned about magnesium, which he says has “trace elements in almost everything.” Since “the vast majority of magnesium comes from China,” he warned that the restrictions will “drastically affect just about every product we make in the US.” Dr. Bill Anderson at AeroDef Manufacturing 2025. Photo by 3D Printing Industry. The future of 3D printing for defense Despite these concerns, additive manufacturing is rapidly becoming a vital asset for defense applications. It offers value in strengthening supply chains, enhancing combat capabilities, reducing lead times, and replenishing depleted weapon stockpiles. The Pentagon has taken note, committing significant investment to scale domestic 3D printing capacity and cultivate a resilient network of additive manufacturing suppliers. Rosman highlighted the growing market opportunity for 3D printing in defense, citing data from Additive Manufacturing Research (AM Research). In its 2024 report, the New York-based firm projected that DOD spending on 3D printing will exceed $1 billion in 2025, up from $800 million last year. U.S. investment is projected to rise steadily through the decade, reaching $2.6 billion by 2030. These findings align with the views shared by speakers in Detroit. As geopolitical tensions and security concerns intensify, 3D printing is poised to play a larger role in strengthening global defense capabilities. While Europe is expected to ramp up adoption in the coming years, the United States is already investing heavily to secure a leading position in the additive manufacturing landscape. While challenges persist, increased collaboration between state and industry seems set to accelerate additive manufacturing adoption within America’s defense industrial base. DOD 3D printing spending growth projections. Image via Additive Manufacturing Research. Read all the 3D printing news from RAPID + TCT 2025.Who won the 2024 3D Printing Industry Awards? Subscribe to the 3D Printing Industry newsletter to keep up with the latest 3D printing news.You can also follow us on LinkedIn, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.Featured image shows Major General Michael Lalor speaking at AeroDef Manufacturing 2025. Photo by 3D Printing Industry.0 Commentaires 0 Parts 25 Vue

3DPRINTINGINDUSTRY.COMRAPID + TCT 2025 3D Printing for Defense: New Insights from the U.S. Army, BlueForge Alliance, Boeing, and MoreAerospace and defense now rank among the largest and most valuable sectors adopting additive manufacturing. Ongoing international supply chain disruptions, rising geopolitical tensions, and global conflicts threaten access to critical equipment and components vital for national security. In response, defense agencies are turning to 3D printing to cut lead times, localize production, repair equipment, and restock depleted inventories. This growing focus on 3D printing for defense was evident at RAPID + TCT 2025, which co-located with the eighth edition of SME’s AeroDef Manufacturing 2025 expo. A large section of the show floor at Detroit’s Huntington Place was dedicated to key exhibitors within the military technology ecosystem. This included heat exchanger manufacturer Conflux Technology, aerospace 3D printing firm Hyphen Innovations, and US defense manufacturing accelerator LIFT. Read more RAPID + TCT 2025 news and executive insights AeroDef also featured a stacked conference track. Expert-led presentations and panels provided insights into the value, opportunities, and challenges facing the defense industrial base. Major General Michael Lalor of the U.S. Army highlighted 3D printing’s role in sustaining 70% of the infantry’s combat inventory. He also emphasized its importance for building an “arsenal of democracy” in Detroit. RHH Advisory’s Tali Rosman identified 3D printing’s potential to increase the pace of American manufacturing. This is particularly significant given that China’s shipbuilding capacity is currently 350 times greater than that of the United States. A BlueForge Alliance-led panel discussed how to accelerate production in the U.S. Navy’s industrial base, highlighting the value and challenges surrounding 3D printing adoption. Elsewhere, Dr. Bill Anderson highlighted the cybersecurity threats that malicious foreign actors pose to the digital ecosystem of additive manufacturing. Boeing’s Daniel Braley was also on the agenda. He highlighted vulnerabilities in the supply chain for critical minerals and materials, citing the “threat of the U.S. going to full-scale war in one to two years.” As geopolitical tensions rise and global supply chains constrict, all speakers broadly agreed that 3D printing will become a critical strategic pillar in safeguarding the West’s defense industrial base. The AeroDef Manufacturing 2025 expo show floor. Photo by 3D Printing Industry. Major General Michael Lalor: Advanced manufacturing at U.S. Army TACOM Major General Michael B. Lalor, Commanding General of U.S. Army Tank-automotive and Armaments Command (TACOM), opened the AeroDef conference with a welcome address. Headquartered at Detroit Arsenal, the Command manages 70% of the U.S. Army’s ground combat inventory. “If a soldier drives it, shoots it, or wears it, we sustain it,” Lalor explained. TACOM oversees a $30 billion annual budget and manages over 3,500 weapon systems. According to the former M1A1 Tank Platoon Leader, these include everything from Abrams and Bradley tanks to eight-wheeled Stryker armored fighting vehicles and artillery systems. TACOM maintains a global presence. At any given time, about 350 personnel across 70 “flyaway teams” operate overseas, supporting supply chain operations for units in the field. Collaboration with industry partners is vital for TACOM’s operations. He noted that technological evolution and supply chain complexities demand new levels of collaboration that transcend “international and traditional boundaries.” Lalor added that TACOM is leading the U.S. Army in advanced manufacturing. 3D printing is being leveraged to fabricate customized parts on demand, reducing reliance on lengthy lead times. TACOM’s Major General highlighted that the Command has seen “amazing results” through this adoption. Over the past year, TACOM has developed its Battle Damage Repair and Fabrication Program (BDRF). The initiative leverages additive manufacturing to produce temporary replacement parts for damaged military vehicles. This reduces downtime and increases operational readiness, allowing critical warfighting equipment to be returned to the battlefield in less time. Over 40,000 vehicle parts have been assessed for additive manufacturability in collaboration with the U.S. Army DEVCOM Ground Vehicle Systems Center and TACOM Integrated Logistics Support Center. From this, TACOM’s Rock Island Arsenal – Joint Manufacturing and Technology Center in Illinois has 3D printed more than 600 3D CAD models. According to Lalor, these efforts are vital to relieving the substantial pressure on America’s few remaining foundries. The U.S. Army’s only operational foundry at Rock Island has seen its workload quadruple over the past 18 months amid a dearth of domestic castings and forgings capabilities. Lalor revealed that Rock Hill Arsenal’s additive manufacturing technologies will be ASTM 9100 compliant by June 2025, when it will ramp up production of aerospace and aviation-certified parts. “There are gaps to close, and that arsenal is part of the solution,” he added. Major General Michael Lalor speaking at AeroDef Manufacturing 2025. Photo by 3D Printing Industry. The value of 3D printing for defense In a separate presentation, Tali Rosman, a Business and M&A advisor at RHH Advisory and former Elem Additive CEO, shared her perspective on the defense opportunity for 3D printing. Rosman emphasized the U.S. Department of Defense’s (DOD) growing adoption of additive manufacturing, suggesting that the Pentagon is “arguably the largest user” of additive manufacturing based on dollars spent. However, this adoption comes amid a challenging point for the Pentagon. According to Rosman, “China is outpacing the U.S. in terms of manufacturing.” Notably, she highlighted that China’s shipbuilding capacity is 350 times that of the United States. Amid this threat, the DOD is adopting additive manufacturing “in earnest” to secure the U.S. defense supply chain. While it can take years to build conventional manufacturing plants, some 3D printing technologies can start fabricating parts in weeks. In today’s “volatile and uncertain world,” that speed makes the technology especially appealing. Rosman highlighted expeditionary manufacturing as one key application for 3D printing. She emphasized that conflict in Ukraine has “paved the way” for its remote deployment. Ukrainian soldiers are leveraging metal additive manufacturing, including cold spray 3D printers from SPEE3D, to increase equipment uptime and localize critical supply chains. The U.S. Navy has also installed 3D printers on warships to conduct repairs and fabricate replacement parts at the point of need. Last year, SPEE3D’s XSPEE3D and Snowbird Technologies’ SAMM Tech hybrid DED manufacturing system were deployed during the Rim of the Pacific (RIMPAC) exercise in Hawaii. During the trial, Navy personnel sought to reduce the delivery time of critical parts from days to hours. Additionally, Rosman highlighted increased DOD funding to restock its depleted missile arsenals using 3D printing. She pointed to Albuquerque-based aerospace firm X-Bow Launch Systems, which recently received an additional $9.85 million from the DOD to advance research into 3D printed solid rocket motors (SRMs). This new capital sees the company’s current DOD contract value rise to $28.67 million, while its total U.S. defense funding has exceeded $97 million. Similarly, the Pentagon has backed Ursa Major to 3D print missile SRMs. Last December, the Colorado-based firm completed successful flight testing for the U.S. Army. Daniel Jablonsky, Ursa Major’s CEO, claimed that the company’s Lynx 3D printing technology unlocked “unprecedented timelines,” with nearly 300 SRM static test fires completed in 2024. Looking ahead, Rosman anticipates that 3D printing will play an increasing role for many of America’s allies. European countries are expected to ramp up defense funding, following the Trump administration’s call for increased security spending among NATO members. For instance, Germany’s defense spending could grow to 3% of GDP by 2027, potentially exceeding 3.5% after that, according to Goldman Sachs research. Rosman believes a “disproportionate” amount of Europe’s funding will be “flowing into the additive manufacturing sector” in the coming years. Indeed, the UK recently outlined plans to accelerate 3D printing for defense. The Ministry of Defense (MOD) aims to increase investment to incentivise adoption, adapt policies to remove barriers, and increasingly integrate additive manufacturing into the defense supply chain. Snowbird Technologies’ 3D printer at RAPID + TCT 2025. Photo by 3D Printing Industry. Additive manufacturing bolsters the US Navy’s industrial base The role of additive manufacturing in the U.S. submarine industrial base (SIB) is also growing. Leading this effort is BlueForge Alliance (BFA), a nonprofit defense integrator. Headquartered in Bryan, Texas, BFA coordinates manufacturing, recruitment, and technology integration to support the U.S. Navy’s manufacturing supply chain. During a panel discussion, Tim Shinbara, BFA’s Chief Strategy Officer, sat down with James Hockey, Director of metal 3D printing service provider Incodema3D, and Greg Mallon, Chief Strategy Officer of engineering and manufacturing firm GSE Dynamics. Incodema3D and GSE Dynamics are among the roughly 16,000 companies working in America’s ship and submarine manufacturing sector. Mallon identified workforce challenges as stunting the growth of America’s maritime industrial base. He noted that over the past 30 years, the U.S. has shifted from a goods-based economy to one driven by digital and service industries. The result? A shrunken manufacturing workforce, down from 3 million to just over a million workers. “That has left the defense industrial base very atrophied,” Mallon added. Additive manufacturing firms, like Incodema3D, are no less affected. “Our biggest problem is still talent,” agreed Hockey. “We can’t hire people fast enough.” The 27-year 3D printing veteran explained that Incodema3D needs to be growing 25% every year “just to keep up with the scaling we’ve already done.” However, the company, which operates out of Freeville, New York, has only grown 30% since its founding in 2013. BluForge Alliance is working to alleviate these shortfalls through buildsubmarines.com, a website that connects workers with employers in the submarine industrial base. According to Shinbara, the recruitment tool offers a low-cost and effective solution to workforce challenges. “It’s only eight cents for someone to apply, and we found it’s about $700 per person to be hired,” he explained. Buildsubmarines.com sign in Detroit. Photo by 3D Printing Industry. Adoption also remains a core challenge within maritime manufacturing. In particular, Hockey identified the need for customers to embrace design for additive manufacturing (DfAM) and understand where the value lies. He highlighted a common issue with additive manufacturing: the assumption that it’s always the faster solution. Specifically, customers are increasingly requesting low-volume casting for legacy parts. Hockey explained that these applications offer little value unless the design includes novel geometries or features enabled by 3D printing. For Mallon, the roadblocks to adoption go beyond the machinery, citing “a lack of enthusiasm to adopt that new technology.” He highlighted a “resistance to change” among experienced workers, often due to job security concerns or comfort with legacy systems. However, there is stronger enthusiasm for 3D printing among younger workers, who “embrace the technology much faster.” Looking to the future of maritime manufacturing, Mallon believes hope lies in predictable defense programs and automation. “When you look at the Navy’s 30-year shipbuilding plan, each year it changes,” he said. “It’s hard to follow.” Mallon believes increased predictability would allow customers to follow through on programs and prioritize execution. Moreover, GSE Dynamics’ Chief Strategy Officer believes increased automation will improve efficiency and speed. Hockey echoed this sentiment, highlighting his company’s internal push for tighter integration between additive manufacturing and CNC machining. Hockey predicted that streamlined workflows will ease staffing pressures while also elevating the overall skill level of the workforce. Shinbara, surveying the broader context from Washington, D.C., concluded with a hopeful note. “The policy, posture, and funding are starting to align,” he said. “It’s probably one of the few times outside of World War Two” that the U.S. has seen this level of policy and financial momentum. Tim Shinbara, Greg Mallon, and James Hockey (L-R). Photo by 3D Printing Industry. Cybersecurity threats and logistical challenges Security threats and supply chain challenges also jeopardize adoption and growth. Dr. Bill Anderson, Principal Product Manager at Mattermost, underscored major cybersecurity concerns. He pointed to the risks tied to additive manufacturing’s expanding digital footprint. Anderson opened his presentation with a stark warning: “The government is under attack from foreign adversaries.” He emphasized that government suppliers, contract manufacturers, and OEMs face significant risk. The digital security expert observed that even manufacturers far from the front lines are under threat, warning, “You’re being attacked now, you probably just don’t know it.” The University of Waterloo alumnus explained that, in wartime, the West’s adversaries may look to shut down suppliers’ systems. This could have knock-on effects, impacting the military and government’s ability to operate. According to Anderson, about 70% of cyberattacks on the defense industrial base are committed by nation states. He pointed to China as a major threat, particularly Volt Typhoon, reportedly a Chinese state-sponsored hacker group engaged in cyberespionage. In 2023, this advanced persistent threat (APT) breached commercial and Navy networks near Guam. While the U.S. successfully thwarted the intrusion, the attack could have severed communications across the Pacific. Such a capability would carry serious strategic consequences, particularly amid escalating tensions over Taiwan. Security threats also impact the supply of critical materials. Braley, a Technical Fellow at Boeing, described the global supply chain as a “perfect storm.” He explained that intensifying threats from Russia, North Korea, China, and Iran have “severely affected” America’s ability to procure raw materials and manufactured parts. Tightening U.S. and international regulations constrain the flow of materials essential to America’s defense manufacturing. According to Braley, “the real issue for the aerospace industry” lies in recent amendments to the National Defense Authorization Act (NDAA), which introduce new import restrictions. Braley noted that most titanium powder used in metal 3D printing is sourced from China. Under the updated NDAA, the DOD could be barred from procuring Chinese titanium powder starting in June 2026. The legislation will also restrict imports of key steel and metal alloys, including nickel, iron, cobalt, zirconium, and their derivatives. Braley is especially concerned about magnesium, which he says has “trace elements in almost everything.” Since “the vast majority of magnesium comes from China,” he warned that the restrictions will “drastically affect just about every product we make in the US.” Dr. Bill Anderson at AeroDef Manufacturing 2025. Photo by 3D Printing Industry. The future of 3D printing for defense Despite these concerns, additive manufacturing is rapidly becoming a vital asset for defense applications. It offers value in strengthening supply chains, enhancing combat capabilities, reducing lead times, and replenishing depleted weapon stockpiles. The Pentagon has taken note, committing significant investment to scale domestic 3D printing capacity and cultivate a resilient network of additive manufacturing suppliers. Rosman highlighted the growing market opportunity for 3D printing in defense, citing data from Additive Manufacturing Research (AM Research). In its 2024 report, the New York-based firm projected that DOD spending on 3D printing will exceed $1 billion in 2025, up from $800 million last year. U.S. investment is projected to rise steadily through the decade, reaching $2.6 billion by 2030. These findings align with the views shared by speakers in Detroit. As geopolitical tensions and security concerns intensify, 3D printing is poised to play a larger role in strengthening global defense capabilities. While Europe is expected to ramp up adoption in the coming years, the United States is already investing heavily to secure a leading position in the additive manufacturing landscape. While challenges persist, increased collaboration between state and industry seems set to accelerate additive manufacturing adoption within America’s defense industrial base. DOD 3D printing spending growth projections. Image via Additive Manufacturing Research. Read all the 3D printing news from RAPID + TCT 2025.Who won the 2024 3D Printing Industry Awards? Subscribe to the 3D Printing Industry newsletter to keep up with the latest 3D printing news.You can also follow us on LinkedIn, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.Featured image shows Major General Michael Lalor speaking at AeroDef Manufacturing 2025. Photo by 3D Printing Industry.0 Commentaires 0 Parts 25 Vue -

WWW.ZDNET.COMAdobe Firefly now generates AI images with OpenAI, Google, and Flux models - how to access themNew models include the Firefly Image Model 4, GPT-4o image model, and Imagen 3.0 Commentaires 0 Parts 27 Vue

WWW.ZDNET.COMAdobe Firefly now generates AI images with OpenAI, Google, and Flux models - how to access themNew models include the Firefly Image Model 4, GPT-4o image model, and Imagen 3.0 Commentaires 0 Parts 27 Vue -

WWW.FORBES.COMFrom Overworked To Optimized: Technology And The Future Of Primary CareRather than replacing physicians, technology can help redefine their roles, enabling a more patient-centered, transdisciplinary approach.0 Commentaires 0 Parts 21 Vue

WWW.FORBES.COMFrom Overworked To Optimized: Technology And The Future Of Primary CareRather than replacing physicians, technology can help redefine their roles, enabling a more patient-centered, transdisciplinary approach.0 Commentaires 0 Parts 21 Vue -

TIME.COMWhy Tax Breaks for Data Centers Could Backfire on StatesAs the AI boom continues to escalate, states have rushed to entice data centers with juicy tax breaks. Data centers not only provide cloud based storage, but also power the training of increasingly powerful AI models. Lawmakers in more than 30 states have carved out tax incentives for data center companies, arguing that without them, the data centers wouldn’t come—and that their presence is essential toward growing property and income tax revenue, and driving economic development. But some economists and policy experts have started to question this logic. In a new study from Good Jobs First, a nonprofit research group, authors Greg LeRoy and Kasia Tarczynska find that data center tax breaks have swelled to billions of dollars in lost revenue for states a year—and that those losses, for some states, actually outweigh the tax revenue that the data centers bring in.“It’s a billion-dollar subsidy to the industry that is dominated by a few big tech companies,” says Tarczynska. Conversely, other economists and data center lobbyists argue that the industry’s overall impact vastly outweighs those potential losses, including by supporting local infrastructure and catalyzing further investment. The paper’s authors contend that even if there are positives, the public doesn’t yet know the extent of their costs, which are often obscured by tax privacy laws, confidentiality agreements or a sheer lack of research. “All politicians and corporations want to talk about are the benefits, while ignoring or downplaying the costs of development subsidies,” LeRoy writes in an email to TIME. “Let the companies compete on quality and price, not on how much they can extract from taxpayers and distort economic development and land use.” ‘Up and up and up’Many data center agreements are shrouded in secrecy, which means that the paper’s authors had limited data to draw from. At least 12 states, Leroy says, share no data on tax expenditures for data centers at all. But by looking through state budgets and other fiscal reports, the paper’s authors found that at least 10 states are missing out on $100 million per year in tax revenue. Much of this comes from subsidies for equipment like expensive servers, which need to be swapped out every few years. Many of these exemptions are uncapped in terms of their dollar amounts or time limit. This means that as data centers grow in size and power, so do the subsidies, forcing states to drastically recalculate their budget projections. In Texas, the cost projection for its data center sales tax exemption program increased from $157 million in 2023 to $1 billion this year. “These hyperscalers come and spend a lot of money, and the tax breaks are going up and up and up,” says Tarczynska. Data center proponents offer several rebuttals. First, they argue that most states already offer tax exemptions for manufacturing equipment—and these new carveouts are simply bringing the data center industry in line with those rules. They also argue that without subsidies, data center companies would set up shop elsewhere. In 2022, a tax incentive evaluation study from the Carl Vinson Institute of Government at the University of Georgia found that 90% of data center activity in Georgia was due to the incentive—implying that without those tax breaks, all of that business would essentially vanish. However, there is debate in economic circles around how much incentives actually cause economic activity. A 2018 paper from the economist Timothy Bartik found that the percentage of firms who made a location decision based on an incentive was much lower than the Vinson number: between 2 and 25 percent. “You need to allow for the fact that for some incentives, you would have gotten some data center activity anyway,” Bartik tells TIME. “My view is that there are potentially some fiscal benefits of data centers, but the industry is vastly overstating them.”A debate in GeorgiaData centers are a particular point of contention in Georgia, where they are growing at an unprecedented rate, particularly in the Atlanta metro area. State reports show that data center incentives have waived at least $163 million in local state and sales tax collections each year since 2022. The Governor’s Office of Planning and Budget estimates those incentives will surpass $327 million next year. Last year, Georgia state senate finance committee chairman Chuck Hufstetler, a Republican, spearheaded efforts to scrutinize tax breaks, resulting in the state legislature passing a bill halting tax breaks to data centers for two years. But Governor Brian Kemp vetoed it, saying that it would harm investment plans. Hufstetler tells TIME that the incentives are unnecessary. “The thing I’ve seen is that it's a competition of who can build it the quickest. It’s more important to them that they’re built first versus the cost,” he says. “I’m not opposed to data centers. But if they’re going to come, it shouldn’t be on the backs of local people, and they should be paying all their costs.“ Georgia state senator Sally Harrell, a Democrat, agrees, and contends that data centers do not provide long term jobs or serve local businesses. Data centers typically employ just a few dozen workers, which pales in comparison to factories of similar sizes. “The local community is left footing the bill for big, national companies that generate economic activity elsewhere,” she writes in an email to TIME. The aforementioned 2022 Vinson study in Georgia found that the amount of revenue forgone due to exemptions far exceeded the tax revenue generated by data centers, resulting in a negative state fiscal impact of $18 million in 2021. The study argued, however, that because the data centers would mostly not have been established without the incentive, their overall economic impact was significantly positive.Nathan Jensen, a professor at the University of Texas Austin, argues that this line of reasoning is flawed. “It’s always a bit of a trick where they cite the economic impact: You could go to a Walmart parking lot and throw $100 in the air, and that would have a net positive economic impact,” he says. “The key is the fiscal impact: does the state make its money back?” A defense of data centersStephen Hartka, vice president of research at the Virginia Economic Development Partnership, has a different perspective. He says that the “overwhelming majority” of data centers in Virginia were brought to the state by incentives. He argues that economists who only look at state tax revenues miss the fact that Virginia’s tax structure sends more benefits to smaller localities—who especially benefit from the property taxes that data centers pay. He also says that data centers can be particularly valuable in rural areas that have struggled to attract businesses. “Data centers are a very good fit for these rural areas, because they don't require a lot of people and they generate a ton of revenue for local governments,” he says. “They are financial boons to these communities that might not have many other options.” However, there has been a groundswell of activism against data centers in many Virginian communities. Last year, Ian Lovejoy, a Republican state delegate in Virginia, told TIME that data centers were the “number one issue we hear about from our constituents.” Residents expressed concerns about data centers threatening electricity and water access, and worried that taxpayers may have to foot the bill for future power lines. Across the country, communities have complained about data centers emitting pollutants and harming quality of life. LeRoy, the author of the Good Jobs First study, cautions localities from making “land use decisions based not on jobs or quality of life, but on how much they can get in tax revenue from a particular use.” He points to a precursor: when localities rushed to build malls and big-box retail centers for the sales and property taxes they brought in, only for them to be deserted when e-commerce took its place. The direction of data centers and their national expansion is still hazy. But watchdogs like LeRoy and policy experts like Jensen wish that more data was provided about the massive tradeoffs that states are making, and whether they are worth it. “I think the simple story is these are heavily subsidized capital intensive investments, which makes a pretty tough value proposition for communities,” Jensen says. “Because it's the tax revenues that are the biggest benefit, and you're giving a ton of that back.”0 Commentaires 0 Parts 23 Vue

TIME.COMWhy Tax Breaks for Data Centers Could Backfire on StatesAs the AI boom continues to escalate, states have rushed to entice data centers with juicy tax breaks. Data centers not only provide cloud based storage, but also power the training of increasingly powerful AI models. Lawmakers in more than 30 states have carved out tax incentives for data center companies, arguing that without them, the data centers wouldn’t come—and that their presence is essential toward growing property and income tax revenue, and driving economic development. But some economists and policy experts have started to question this logic. In a new study from Good Jobs First, a nonprofit research group, authors Greg LeRoy and Kasia Tarczynska find that data center tax breaks have swelled to billions of dollars in lost revenue for states a year—and that those losses, for some states, actually outweigh the tax revenue that the data centers bring in.“It’s a billion-dollar subsidy to the industry that is dominated by a few big tech companies,” says Tarczynska. Conversely, other economists and data center lobbyists argue that the industry’s overall impact vastly outweighs those potential losses, including by supporting local infrastructure and catalyzing further investment. The paper’s authors contend that even if there are positives, the public doesn’t yet know the extent of their costs, which are often obscured by tax privacy laws, confidentiality agreements or a sheer lack of research. “All politicians and corporations want to talk about are the benefits, while ignoring or downplaying the costs of development subsidies,” LeRoy writes in an email to TIME. “Let the companies compete on quality and price, not on how much they can extract from taxpayers and distort economic development and land use.” ‘Up and up and up’Many data center agreements are shrouded in secrecy, which means that the paper’s authors had limited data to draw from. At least 12 states, Leroy says, share no data on tax expenditures for data centers at all. But by looking through state budgets and other fiscal reports, the paper’s authors found that at least 10 states are missing out on $100 million per year in tax revenue. Much of this comes from subsidies for equipment like expensive servers, which need to be swapped out every few years. Many of these exemptions are uncapped in terms of their dollar amounts or time limit. This means that as data centers grow in size and power, so do the subsidies, forcing states to drastically recalculate their budget projections. In Texas, the cost projection for its data center sales tax exemption program increased from $157 million in 2023 to $1 billion this year. “These hyperscalers come and spend a lot of money, and the tax breaks are going up and up and up,” says Tarczynska. Data center proponents offer several rebuttals. First, they argue that most states already offer tax exemptions for manufacturing equipment—and these new carveouts are simply bringing the data center industry in line with those rules. They also argue that without subsidies, data center companies would set up shop elsewhere. In 2022, a tax incentive evaluation study from the Carl Vinson Institute of Government at the University of Georgia found that 90% of data center activity in Georgia was due to the incentive—implying that without those tax breaks, all of that business would essentially vanish. However, there is debate in economic circles around how much incentives actually cause economic activity. A 2018 paper from the economist Timothy Bartik found that the percentage of firms who made a location decision based on an incentive was much lower than the Vinson number: between 2 and 25 percent. “You need to allow for the fact that for some incentives, you would have gotten some data center activity anyway,” Bartik tells TIME. “My view is that there are potentially some fiscal benefits of data centers, but the industry is vastly overstating them.”A debate in GeorgiaData centers are a particular point of contention in Georgia, where they are growing at an unprecedented rate, particularly in the Atlanta metro area. State reports show that data center incentives have waived at least $163 million in local state and sales tax collections each year since 2022. The Governor’s Office of Planning and Budget estimates those incentives will surpass $327 million next year. Last year, Georgia state senate finance committee chairman Chuck Hufstetler, a Republican, spearheaded efforts to scrutinize tax breaks, resulting in the state legislature passing a bill halting tax breaks to data centers for two years. But Governor Brian Kemp vetoed it, saying that it would harm investment plans. Hufstetler tells TIME that the incentives are unnecessary. “The thing I’ve seen is that it's a competition of who can build it the quickest. It’s more important to them that they’re built first versus the cost,” he says. “I’m not opposed to data centers. But if they’re going to come, it shouldn’t be on the backs of local people, and they should be paying all their costs.“ Georgia state senator Sally Harrell, a Democrat, agrees, and contends that data centers do not provide long term jobs or serve local businesses. Data centers typically employ just a few dozen workers, which pales in comparison to factories of similar sizes. “The local community is left footing the bill for big, national companies that generate economic activity elsewhere,” she writes in an email to TIME. The aforementioned 2022 Vinson study in Georgia found that the amount of revenue forgone due to exemptions far exceeded the tax revenue generated by data centers, resulting in a negative state fiscal impact of $18 million in 2021. The study argued, however, that because the data centers would mostly not have been established without the incentive, their overall economic impact was significantly positive.Nathan Jensen, a professor at the University of Texas Austin, argues that this line of reasoning is flawed. “It’s always a bit of a trick where they cite the economic impact: You could go to a Walmart parking lot and throw $100 in the air, and that would have a net positive economic impact,” he says. “The key is the fiscal impact: does the state make its money back?” A defense of data centersStephen Hartka, vice president of research at the Virginia Economic Development Partnership, has a different perspective. He says that the “overwhelming majority” of data centers in Virginia were brought to the state by incentives. He argues that economists who only look at state tax revenues miss the fact that Virginia’s tax structure sends more benefits to smaller localities—who especially benefit from the property taxes that data centers pay. He also says that data centers can be particularly valuable in rural areas that have struggled to attract businesses. “Data centers are a very good fit for these rural areas, because they don't require a lot of people and they generate a ton of revenue for local governments,” he says. “They are financial boons to these communities that might not have many other options.” However, there has been a groundswell of activism against data centers in many Virginian communities. Last year, Ian Lovejoy, a Republican state delegate in Virginia, told TIME that data centers were the “number one issue we hear about from our constituents.” Residents expressed concerns about data centers threatening electricity and water access, and worried that taxpayers may have to foot the bill for future power lines. Across the country, communities have complained about data centers emitting pollutants and harming quality of life. LeRoy, the author of the Good Jobs First study, cautions localities from making “land use decisions based not on jobs or quality of life, but on how much they can get in tax revenue from a particular use.” He points to a precursor: when localities rushed to build malls and big-box retail centers for the sales and property taxes they brought in, only for them to be deserted when e-commerce took its place. The direction of data centers and their national expansion is still hazy. But watchdogs like LeRoy and policy experts like Jensen wish that more data was provided about the massive tradeoffs that states are making, and whether they are worth it. “I think the simple story is these are heavily subsidized capital intensive investments, which makes a pretty tough value proposition for communities,” Jensen says. “Because it's the tax revenues that are the biggest benefit, and you're giving a ton of that back.”0 Commentaires 0 Parts 23 Vue -

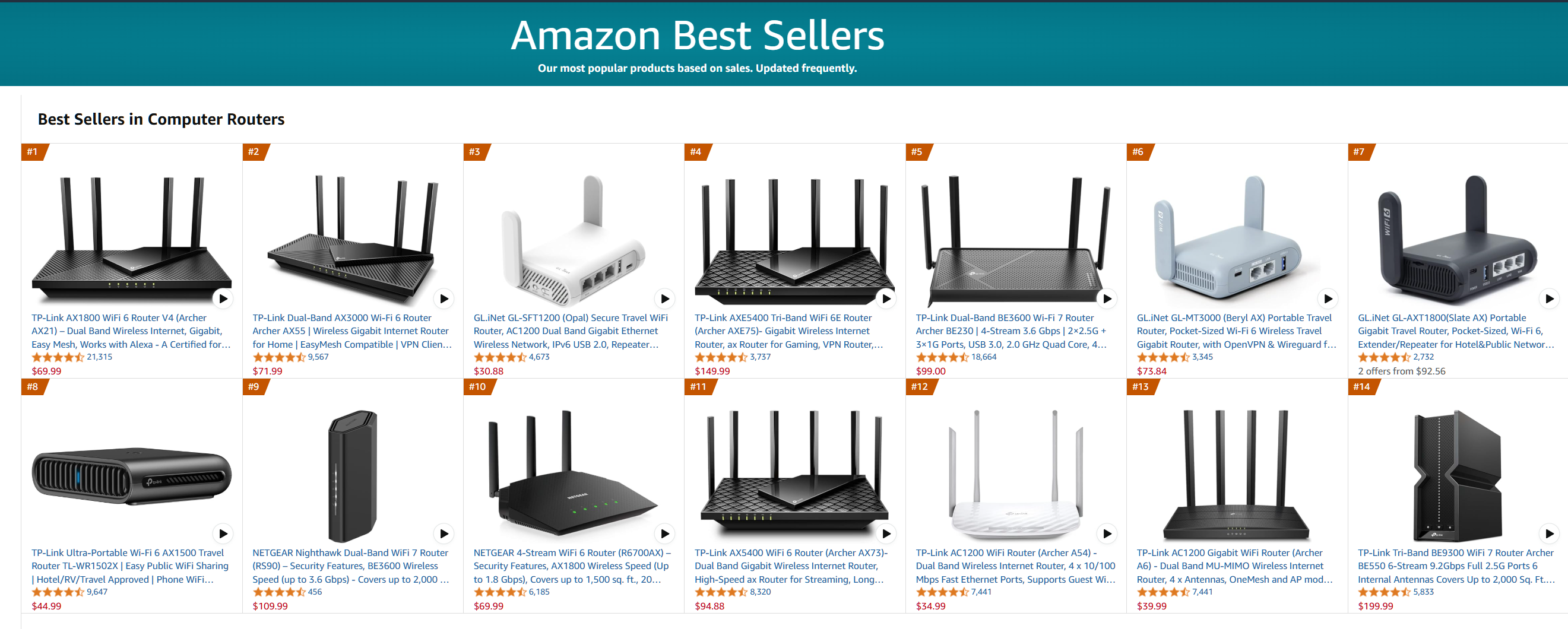

WWW.TECHSPOT.COMTP-Link's router pricing and China ties under US government investigationIn a nutshell: TP-Link Systems, one of the most popular router brands in the United States, has become the subject of a criminal antitrust investigation by the Department of Justice. According to reports, the China-linked company's pricing strategies and potential national security risks will be examined by the DoJ and the Commerce Department. The affordability of TP-Link's routers is part of what makes them so popular. Prosecutors at the DoJ are examining whether the company engaged in predatory pricing to undercut competitors and dominate the US market, writes Bloomberg. The probe began in 2024 under President Biden and continues today under the Trump administration. TP-Link is also being investigated by the Commerce Department over whether its ties to China pose a security threat. It was reported in December that an office of the Commerce Department had subpoenaed TP-Link, and that its routers could be banned in the US over national security concerns. TP-Link was founded by brothers Zhao Jianjun and Zhao Jiaxing in 1996. In 2008, TP-Link USA was set up to market and service products in North America, but ownership, management and supply chain all still reported to the Shenzhen-based TP-Link parent. In 2024, TP-Link USA completed a merger with TP-Link's non-Chinese operations to form TP-Link Systems Inc., headquartered in Irvine, California. This "organisational separation" from the Chinese company ensures each side has its own shareholding structure, board, R&D, production, marketing and support teams. Regulators and lawmakers are still reviewing whether the structural split truly insulates TP-Link's US arm from Chinese legal jurisdiction – hence the current antitrust and national-security probes. // Related Stories TP-Link has around 65% of the US market for routers used in homes and small businesses. Twelve of the top twenty best-selling routers on Amazon are TP-Link models, including the number one (TP-Link AX1800 WiFi 6 Router V4) and number two (TP-Link Dual-Band AX3000 Wi-Fi 6 Router Archer AX55) top sellers. In October 2024, Microsoft exposed a complex network of compromised devices that Chinese hackers used to launch highly evasive password spray attacks against Microsoft Azure customers. The network, dubbed CovertNetwork-1658, had been actively stealing credentials since August 2023. The attacks used a botnet of thousands of small office and home office (SOHO) routers, cameras, and other Internet-connected devices. At its peak, there were more than 16,000 devices in the botnet, most of which were TP-Link routers. There's a history of security flaws being discovered in TP-Link routers. A critical vulnerability with a CVSS score of 10.0 was found in the Archer C5400X tri-band router for gaming in May 2024, and in 2023, it was reported that Chinese state hackers were infecting TP-Link routers with custom, malicious firmware. The latter incident arrived soon after the US government said Mirai Botnet operators were using TP-Link routers for DDoS attacks.0 Commentaires 0 Parts 18 Vue

WWW.TECHSPOT.COMTP-Link's router pricing and China ties under US government investigationIn a nutshell: TP-Link Systems, one of the most popular router brands in the United States, has become the subject of a criminal antitrust investigation by the Department of Justice. According to reports, the China-linked company's pricing strategies and potential national security risks will be examined by the DoJ and the Commerce Department. The affordability of TP-Link's routers is part of what makes them so popular. Prosecutors at the DoJ are examining whether the company engaged in predatory pricing to undercut competitors and dominate the US market, writes Bloomberg. The probe began in 2024 under President Biden and continues today under the Trump administration. TP-Link is also being investigated by the Commerce Department over whether its ties to China pose a security threat. It was reported in December that an office of the Commerce Department had subpoenaed TP-Link, and that its routers could be banned in the US over national security concerns. TP-Link was founded by brothers Zhao Jianjun and Zhao Jiaxing in 1996. In 2008, TP-Link USA was set up to market and service products in North America, but ownership, management and supply chain all still reported to the Shenzhen-based TP-Link parent. In 2024, TP-Link USA completed a merger with TP-Link's non-Chinese operations to form TP-Link Systems Inc., headquartered in Irvine, California. This "organisational separation" from the Chinese company ensures each side has its own shareholding structure, board, R&D, production, marketing and support teams. Regulators and lawmakers are still reviewing whether the structural split truly insulates TP-Link's US arm from Chinese legal jurisdiction – hence the current antitrust and national-security probes. // Related Stories TP-Link has around 65% of the US market for routers used in homes and small businesses. Twelve of the top twenty best-selling routers on Amazon are TP-Link models, including the number one (TP-Link AX1800 WiFi 6 Router V4) and number two (TP-Link Dual-Band AX3000 Wi-Fi 6 Router Archer AX55) top sellers. In October 2024, Microsoft exposed a complex network of compromised devices that Chinese hackers used to launch highly evasive password spray attacks against Microsoft Azure customers. The network, dubbed CovertNetwork-1658, had been actively stealing credentials since August 2023. The attacks used a botnet of thousands of small office and home office (SOHO) routers, cameras, and other Internet-connected devices. At its peak, there were more than 16,000 devices in the botnet, most of which were TP-Link routers. There's a history of security flaws being discovered in TP-Link routers. A critical vulnerability with a CVSS score of 10.0 was found in the Archer C5400X tri-band router for gaming in May 2024, and in 2023, it was reported that Chinese state hackers were infecting TP-Link routers with custom, malicious firmware. The latter incident arrived soon after the US government said Mirai Botnet operators were using TP-Link routers for DDoS attacks.0 Commentaires 0 Parts 18 Vue

.jpg?width=1920&height=1920&fit=bounds&quality=70&format=jpg&auto=webp)