0 Comments

0 Shares

10 Views

Directory

Directory

-

Please log in to like, share and comment!

-

WWW.ARTOFVFX.COMSonic the Hedgehog 3What happens when speed meets darkness? Shadow has arrived, and the stakes have never been higher. Sonic, Knuckles, and Tails must unite for an electrifying battle in the new Sonic the Hedgehog 3 trailer!The VFX are made by:ILM (VFX Supervisors: Hayden Landis, Rhys Claringbull)Fin Design + Effects (VFX Supervisor: Roy Malhi)Rising Sun PicturesUntold StudiosThe Production VFX Supervisor is Ged Wright.The Production VFX Producer is Paul Molles.Director: Jeff FowlerRelease Date: December 20, 2024 (USA) Vincent Frei The Art of VFX 2024The post Sonic the Hedgehog 3 appeared first on The Art of VFX.0 Comments 0 Shares 10 Views

WWW.ARTOFVFX.COMSonic the Hedgehog 3What happens when speed meets darkness? Shadow has arrived, and the stakes have never been higher. Sonic, Knuckles, and Tails must unite for an electrifying battle in the new Sonic the Hedgehog 3 trailer!The VFX are made by:ILM (VFX Supervisors: Hayden Landis, Rhys Claringbull)Fin Design + Effects (VFX Supervisor: Roy Malhi)Rising Sun PicturesUntold StudiosThe Production VFX Supervisor is Ged Wright.The Production VFX Producer is Paul Molles.Director: Jeff FowlerRelease Date: December 20, 2024 (USA) Vincent Frei The Art of VFX 2024The post Sonic the Hedgehog 3 appeared first on The Art of VFX.0 Comments 0 Shares 10 Views -

WWW.ARTOFVFX.COMLee: VFX Breakdown by Jellyfish PicturesBreakdown & ShowreelsLee: VFX Breakdown by Jellyfish PicturesBy Vincent Frei - 25/11/2024 In Lee, the remarkable story of Lee Miller is told through stunningly authentic visuals. Discover how Jellyfish Pictures seamlessly crafted invisible effects to transport us to the heart of WWII, from war-torn landscapes to intimate period details! Vincent Frei The Art of VFX 20240 Comments 0 Shares 9 Views

WWW.ARTOFVFX.COMLee: VFX Breakdown by Jellyfish PicturesBreakdown & ShowreelsLee: VFX Breakdown by Jellyfish PicturesBy Vincent Frei - 25/11/2024 In Lee, the remarkable story of Lee Miller is told through stunningly authentic visuals. Discover how Jellyfish Pictures seamlessly crafted invisible effects to transport us to the heart of WWII, from war-torn landscapes to intimate period details! Vincent Frei The Art of VFX 20240 Comments 0 Shares 9 Views -

ENTAGMA.COMGuest Tutorial: Truchet Tiles by Simon FiedlerGuest Tutorial: Truchet Tiles by Simon FiedlerWere very happy to have Houdini magician Simon Fiedler back on the show! Simon will show you how to build and arrange truchet tiles in Houdini! An idea he, oddly enough, got from viral soccer ball making videos!Liked it? Take a second to support Christopher Kopic on Patreon!0 Comments 0 Shares 10 Views

ENTAGMA.COMGuest Tutorial: Truchet Tiles by Simon FiedlerGuest Tutorial: Truchet Tiles by Simon FiedlerWere very happy to have Houdini magician Simon Fiedler back on the show! Simon will show you how to build and arrange truchet tiles in Houdini! An idea he, oddly enough, got from viral soccer ball making videos!Liked it? Take a second to support Christopher Kopic on Patreon!0 Comments 0 Shares 10 Views -

3DPRINTINGINDUSTRY.COMNexa3Ds Avi Reichental Addresses RumorsFormnextbrings together the additive manufacturing community in many ways, and one of those is undeniably gossip! Now, 3DPI does endeavor to scrutinize what we should probably call tips, and it can take a little longer to post on social media as a result. Weve kicked the tires on several such tips this past week; someevenmadeitinto print.Formnext is the worlds largest 3D printing trade show, but the business decision to exhibit must be weighed against the costs and benefits. On one side of the equation are the highly beneficial interactions with customers and even competitors; on the other side, the costs of the booth space and the time of employees required to attend. Given the vast majority of enterprises return year-on-year to exhibit, the positives must outweigh any perceived negatives.A comparison between an enterprises previous presence at a trade show is almost inevitable. Bigger booth, better business? No booth, no company? Well, not always but in the febrile environment of a trade show, rumors thrive, not unlike the notorious Frankfurt Flu. When a company is particularly well known, its absence is more likely to be both noticed and remarked upon. This brings us toNexa3D, whose decision not to exhibit raised questions before, during, and after the recent show.I asked Avi Reichental, chairman and CEO of Nexa3D, about his companys decision not to exhibit at Formnext 2024. Nexa3D was upfront with a public post that we are NOT participating in Formnext, he says, pointing to apost made on LinkedInlast week. Providing a minute-by-minute account of corporate decision-making is one way to fill the information gap that can give rise to rumors and speculation, but with social media posts often getting lost in the deluge; it is not always the best way to ensure a message is heard.Reichental explains that while he made the trip to Frankfurt and met with many partners, suppliers, and customers, the shows timing clashed with our HQ relocation, and our bandwidth is limited.Uncertainty and a spate of general, industry-wide, negative news items may be partially fuelling the show floor talk. Like others in the industry, Nexa3D is undergoing restructuring. Nexa3D did lean out operations and reduced headcount consistent with similar moves industry-wide in order to get to break even, said Reichental.On the existential question of corporate continuity, Reichental stated, Nexa3D did not file for bankruptcy; if we did, it would have been public information instantly as all such filings are public.Formnext 2024 is not Reichentals first rodeo, and given his history in the industry, both professionals and armchair commentators will be watching to see how the next chapter plays out.Want to share insights on key industry trends and the future of 3D printing? Register now to be included in the2025 3D Printing Industry Executive Survey.What3D printing trendsdo the industry leaders anticipate this year?What does theFuture of 3D printinghold for the next 10 years?To stay up to date with the latest 3D printing news, dont forget to subscribe to the3D Printing Industry newsletteror follow us onTwitter, or like our page onFacebook.While youre here, why not subscribe to ourYoutubechannel? Featuring discussion, debriefs, video shorts, and webinar replays.Featured image shows the Nexa XiP Pro. Photo via Nexa3D.0 Comments 0 Shares 11 Views

3DPRINTINGINDUSTRY.COMNexa3Ds Avi Reichental Addresses RumorsFormnextbrings together the additive manufacturing community in many ways, and one of those is undeniably gossip! Now, 3DPI does endeavor to scrutinize what we should probably call tips, and it can take a little longer to post on social media as a result. Weve kicked the tires on several such tips this past week; someevenmadeitinto print.Formnext is the worlds largest 3D printing trade show, but the business decision to exhibit must be weighed against the costs and benefits. On one side of the equation are the highly beneficial interactions with customers and even competitors; on the other side, the costs of the booth space and the time of employees required to attend. Given the vast majority of enterprises return year-on-year to exhibit, the positives must outweigh any perceived negatives.A comparison between an enterprises previous presence at a trade show is almost inevitable. Bigger booth, better business? No booth, no company? Well, not always but in the febrile environment of a trade show, rumors thrive, not unlike the notorious Frankfurt Flu. When a company is particularly well known, its absence is more likely to be both noticed and remarked upon. This brings us toNexa3D, whose decision not to exhibit raised questions before, during, and after the recent show.I asked Avi Reichental, chairman and CEO of Nexa3D, about his companys decision not to exhibit at Formnext 2024. Nexa3D was upfront with a public post that we are NOT participating in Formnext, he says, pointing to apost made on LinkedInlast week. Providing a minute-by-minute account of corporate decision-making is one way to fill the information gap that can give rise to rumors and speculation, but with social media posts often getting lost in the deluge; it is not always the best way to ensure a message is heard.Reichental explains that while he made the trip to Frankfurt and met with many partners, suppliers, and customers, the shows timing clashed with our HQ relocation, and our bandwidth is limited.Uncertainty and a spate of general, industry-wide, negative news items may be partially fuelling the show floor talk. Like others in the industry, Nexa3D is undergoing restructuring. Nexa3D did lean out operations and reduced headcount consistent with similar moves industry-wide in order to get to break even, said Reichental.On the existential question of corporate continuity, Reichental stated, Nexa3D did not file for bankruptcy; if we did, it would have been public information instantly as all such filings are public.Formnext 2024 is not Reichentals first rodeo, and given his history in the industry, both professionals and armchair commentators will be watching to see how the next chapter plays out.Want to share insights on key industry trends and the future of 3D printing? Register now to be included in the2025 3D Printing Industry Executive Survey.What3D printing trendsdo the industry leaders anticipate this year?What does theFuture of 3D printinghold for the next 10 years?To stay up to date with the latest 3D printing news, dont forget to subscribe to the3D Printing Industry newsletteror follow us onTwitter, or like our page onFacebook.While youre here, why not subscribe to ourYoutubechannel? Featuring discussion, debriefs, video shorts, and webinar replays.Featured image shows the Nexa XiP Pro. Photo via Nexa3D.0 Comments 0 Shares 11 Views -

3DPRINTINGINDUSTRY.COMNJII partners with Foundry Lab for superior metal part productionNew Zealand-based metal casting company Foundry Lab has announced the New Jersey Innovation Institute (NJII) as its first commercial customer of DMC-3 digital metal casting (DMC) system.The defense team at the institute will deploy the DMC-3 system as part of the Collaborative, Operationalized, Manufacturing, Engineering, and Training (COMET) initiative. This public-private partnership, involving the U.S. Army DEVCOM Armaments Center (DEVCOM AC), NJII, and the New Jersey Institute of Technology (NJIT), focuses on advancing workforce development in manufacturing for Defense and Homeland Security objectives.Thomas Murphy, Director of Defense Manufacturing Technology at NJII said, We are excited about the opportunity to partner with Foundry Lab to reshore metal casting and aid the limited foundry/casting houses in the U.S. There are many casting applications for our partners and a key element is energizing a new workforce that has limited, hands-on experience with casting. We pride ourselves on being in the early adopter program to bring Foundry Labs technology to the Northeast and our partners.Foundry Lab digital casting. Photo by Michael Petch.Foundry Labs DMC technologyIn November 2021, the company introduced its DMC technology which allows for same-day metal part production from CAD files. This technology merges the design versatility of 3D printing with the efficiency and cost advantages of traditional casting.Compatible with materials such as aluminum, stainless steel, and other alloys, the DMC technology produces dense, functional parts that meet industrial standards. Its design supports seamless integration into existing workflows, offering manufacturers a way to address inefficiencies in production while facilitating functional testing before large-scale manufacturing.Having commercially debuted in June 2024 after a demonstration at Formnext 2023, the adoption of the DMC-3 system is expected to improve efficiency in prototyping and production processes.Foundry Lab highlighted that its DMC-3 system decreases lead times for casting prototypes and production parts from months to hours, which can be particularly beneficial for high-demand environments. This move aligns with national efforts to modernize production methods and strengthen supply chain reliability.Defense applications, often characterized by tight timelines and stringent specifications, are one of the key sectors benefiting from the technology. Foundry Lab notes that its system offers engineers and teams an opportunity to streamline workflows without compromising on quality or precision.Reshoring metal casting capabilities within the United StatesAccording to Foundry Lab, manufacturing trends in the U.S. have seen a sharp decline in domestic metal casting facilities, from 6,150 in 1955 to approximately 1,750 today. Foundry Lab positions its DMC technology as a contributor to reshoring initiatives aimed at rebuilding casting capacity. Supporting domestic production is seen as essential for bolstering supply chain resilience and driving economic growth.A hands-free process lies at the core of the DMC-3, eliminating the need for molten metal pouring. Foundry Lab explains that this approach produces castings more efficiently than traditional methods while meeting industrial standards. In contrast to metal AM, which is often limited to prototypes, this system delivers functional parts ready for both prototyping and large-scale production.NJIIs use of the system also highlights its broader potential across industries. Foundry Lab reports interest from defense and industrial manufacturers exploring how the technology can address specific production challenges while improving cost-effectiveness and timelines.As a result, this partnership between Foundry Lab and NJII aims to show how their approach can contribute to improving efficiency while supporting the modernization of the manufacturing sector.A metal part made using the Foundry Lab process. Photo by Michael Petch.Driving progress in metal casting technologiesBeyond NJII, innovative developments in metal casting are being pursued internationally.Researchers at Aston University, led by Dr. Paul Griffiths, are developing a mathematical model to enhance the liquid metal casting process, supported by an 80,000 EPSRC grant. Starting in April 2024, the 12-month project aims to address the rapid oxidation of lightweight aluminum alloys when exposed to air, a challenge that affects the quality and fatigue life of cast parts.Working with the Grenoble Institute of Technology, the team seeks to understand the interaction between liquid metal flow and the oxide layer above, using a model to reduce defects in industrial manufacturing. Expected outcomes include improved alloy quality, reduced production costs, and lower greenhouse gas emissions from lighter products.In another news, UK-based Enable Manufacturing introduced its Vacuum Additive Casting process, a hybrid approach that combines 3D printed molds and patterns with vacuum casting to create metal parts.According to the company, this method significantly reduces costs compared to direct metal 3D printing by utilizing vacuum casting to draw molten metal into intricate structures. Described as delivering the best of both worlds, the process is said to produce components in over 130 metals while being more cost-effective than both traditional manufacturing methods and metal 3D printing.Catch up on all the news fromFormnext 2024.Voting is now open for the2024 3D Printing Industry Awards.Want to share insights on key industry trends and the future of 3D printing? Register now to be included in the2025 3D Printing Industry Executive Survey.What 3D printing trends do the industry leaders anticipate this year?What does the Future of 3D printing hold for the next 10 years?To stay up to date with the latest 3D printing news, dont forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.While youre here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.Featured image shows Foundry Lab digital casting. Photo by Michael Petch.0 Comments 0 Shares 12 Views

3DPRINTINGINDUSTRY.COMNJII partners with Foundry Lab for superior metal part productionNew Zealand-based metal casting company Foundry Lab has announced the New Jersey Innovation Institute (NJII) as its first commercial customer of DMC-3 digital metal casting (DMC) system.The defense team at the institute will deploy the DMC-3 system as part of the Collaborative, Operationalized, Manufacturing, Engineering, and Training (COMET) initiative. This public-private partnership, involving the U.S. Army DEVCOM Armaments Center (DEVCOM AC), NJII, and the New Jersey Institute of Technology (NJIT), focuses on advancing workforce development in manufacturing for Defense and Homeland Security objectives.Thomas Murphy, Director of Defense Manufacturing Technology at NJII said, We are excited about the opportunity to partner with Foundry Lab to reshore metal casting and aid the limited foundry/casting houses in the U.S. There are many casting applications for our partners and a key element is energizing a new workforce that has limited, hands-on experience with casting. We pride ourselves on being in the early adopter program to bring Foundry Labs technology to the Northeast and our partners.Foundry Lab digital casting. Photo by Michael Petch.Foundry Labs DMC technologyIn November 2021, the company introduced its DMC technology which allows for same-day metal part production from CAD files. This technology merges the design versatility of 3D printing with the efficiency and cost advantages of traditional casting.Compatible with materials such as aluminum, stainless steel, and other alloys, the DMC technology produces dense, functional parts that meet industrial standards. Its design supports seamless integration into existing workflows, offering manufacturers a way to address inefficiencies in production while facilitating functional testing before large-scale manufacturing.Having commercially debuted in June 2024 after a demonstration at Formnext 2023, the adoption of the DMC-3 system is expected to improve efficiency in prototyping and production processes.Foundry Lab highlighted that its DMC-3 system decreases lead times for casting prototypes and production parts from months to hours, which can be particularly beneficial for high-demand environments. This move aligns with national efforts to modernize production methods and strengthen supply chain reliability.Defense applications, often characterized by tight timelines and stringent specifications, are one of the key sectors benefiting from the technology. Foundry Lab notes that its system offers engineers and teams an opportunity to streamline workflows without compromising on quality or precision.Reshoring metal casting capabilities within the United StatesAccording to Foundry Lab, manufacturing trends in the U.S. have seen a sharp decline in domestic metal casting facilities, from 6,150 in 1955 to approximately 1,750 today. Foundry Lab positions its DMC technology as a contributor to reshoring initiatives aimed at rebuilding casting capacity. Supporting domestic production is seen as essential for bolstering supply chain resilience and driving economic growth.A hands-free process lies at the core of the DMC-3, eliminating the need for molten metal pouring. Foundry Lab explains that this approach produces castings more efficiently than traditional methods while meeting industrial standards. In contrast to metal AM, which is often limited to prototypes, this system delivers functional parts ready for both prototyping and large-scale production.NJIIs use of the system also highlights its broader potential across industries. Foundry Lab reports interest from defense and industrial manufacturers exploring how the technology can address specific production challenges while improving cost-effectiveness and timelines.As a result, this partnership between Foundry Lab and NJII aims to show how their approach can contribute to improving efficiency while supporting the modernization of the manufacturing sector.A metal part made using the Foundry Lab process. Photo by Michael Petch.Driving progress in metal casting technologiesBeyond NJII, innovative developments in metal casting are being pursued internationally.Researchers at Aston University, led by Dr. Paul Griffiths, are developing a mathematical model to enhance the liquid metal casting process, supported by an 80,000 EPSRC grant. Starting in April 2024, the 12-month project aims to address the rapid oxidation of lightweight aluminum alloys when exposed to air, a challenge that affects the quality and fatigue life of cast parts.Working with the Grenoble Institute of Technology, the team seeks to understand the interaction between liquid metal flow and the oxide layer above, using a model to reduce defects in industrial manufacturing. Expected outcomes include improved alloy quality, reduced production costs, and lower greenhouse gas emissions from lighter products.In another news, UK-based Enable Manufacturing introduced its Vacuum Additive Casting process, a hybrid approach that combines 3D printed molds and patterns with vacuum casting to create metal parts.According to the company, this method significantly reduces costs compared to direct metal 3D printing by utilizing vacuum casting to draw molten metal into intricate structures. Described as delivering the best of both worlds, the process is said to produce components in over 130 metals while being more cost-effective than both traditional manufacturing methods and metal 3D printing.Catch up on all the news fromFormnext 2024.Voting is now open for the2024 3D Printing Industry Awards.Want to share insights on key industry trends and the future of 3D printing? Register now to be included in the2025 3D Printing Industry Executive Survey.What 3D printing trends do the industry leaders anticipate this year?What does the Future of 3D printing hold for the next 10 years?To stay up to date with the latest 3D printing news, dont forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.While youre here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.Featured image shows Foundry Lab digital casting. Photo by Michael Petch.0 Comments 0 Shares 12 Views -

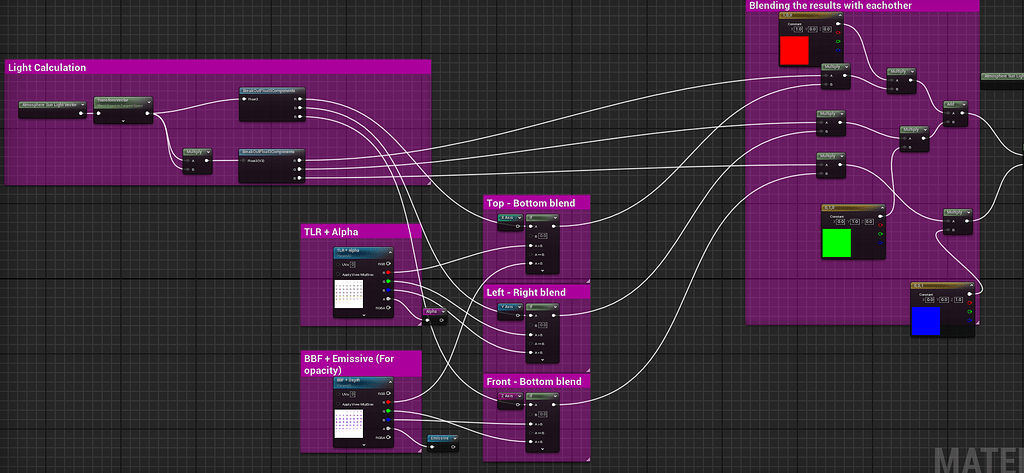

REALTIMEVFX.COM6-Way lightmap Material colors Help - UE5Hi there! Ive been engaged on this topic for the last couple of weeks and i cant get some of the colors of the material right. Im really struggling on how should the colors be multiply and added. I started it following this topic 6-way lightmap WIP and others found on the internet!For reference, im trying to make the colors just like this: https://www.artstation.com/artwork/14lg83Im currently using 2 textures. TLR + alpha, BBF + Emissive, for the colors, Im using the color of the directional light (Atmosphere Sun Light Illuminance on ground), but it just looks weird! What Im i missing here? Blueprint material below! Thanks!!!0 Comments 0 Shares 10 Views

REALTIMEVFX.COM6-Way lightmap Material colors Help - UE5Hi there! Ive been engaged on this topic for the last couple of weeks and i cant get some of the colors of the material right. Im really struggling on how should the colors be multiply and added. I started it following this topic 6-way lightmap WIP and others found on the internet!For reference, im trying to make the colors just like this: https://www.artstation.com/artwork/14lg83Im currently using 2 textures. TLR + alpha, BBF + Emissive, for the colors, Im using the color of the directional light (Atmosphere Sun Light Illuminance on ground), but it just looks weird! What Im i missing here? Blueprint material below! Thanks!!!0 Comments 0 Shares 10 Views -

WWW.ARCHPAPER.COMBernheimer Architecture and Colony Design reimagine a historic Tribeca triplexLevels and LightBernheimer Architecture and Colony Design reimagine a historic Tribeca triplexByKelly Pau November 25, 2024East, Interiors (Brooke Holm)SHAREA young family and long-time client ofBernheimer Architecturehad been living on the fifth floor of a Tribeca apartment in New York. When the floor above became available, the growing family saw an opportunity to expand to accommodate its needs. After the clients acquired roof rights and the sixth floor, the architects reimagined the floorplan and, with the help of furnishing led byColony Designs Jean Lin, turned the new triplex into a light and welcoming home. To accommodate the new level, Bernheimer moved the kitchen from the fifth floor to the sixth, concentrating the social areas above and leaving the fifth floor to more private spaces. Previously the sixth floor was an open loft space for an artist. The architects capitalized on the open plan, raising the roof to get more height into the space, which now holds the living and dining areas, a bathroom, and a home office that can double as a guest bedroom.Read more about the residence on aninteriormag.com. ApartmentsTribeca0 Comments 0 Shares 9 Views

WWW.ARCHPAPER.COMBernheimer Architecture and Colony Design reimagine a historic Tribeca triplexLevels and LightBernheimer Architecture and Colony Design reimagine a historic Tribeca triplexByKelly Pau November 25, 2024East, Interiors (Brooke Holm)SHAREA young family and long-time client ofBernheimer Architecturehad been living on the fifth floor of a Tribeca apartment in New York. When the floor above became available, the growing family saw an opportunity to expand to accommodate its needs. After the clients acquired roof rights and the sixth floor, the architects reimagined the floorplan and, with the help of furnishing led byColony Designs Jean Lin, turned the new triplex into a light and welcoming home. To accommodate the new level, Bernheimer moved the kitchen from the fifth floor to the sixth, concentrating the social areas above and leaving the fifth floor to more private spaces. Previously the sixth floor was an open loft space for an artist. The architects capitalized on the open plan, raising the roof to get more height into the space, which now holds the living and dining areas, a bathroom, and a home office that can double as a guest bedroom.Read more about the residence on aninteriormag.com. ApartmentsTribeca0 Comments 0 Shares 9 Views -

WWW.ARCHPAPER.COMIntroducing Kawneers new IR 521 / 521T / 521UT Storefront Framing System: Where protection meets perfectionKawneers new IR 521 Storefront Framing System offers the reliability of a Kawneer storefront system with exceptional innovation to meet industry needs. Kawneer has brought together the elements you need to enhance storefront projects in one unique framing system. Reimagining interiors and exteriors with sleek looks and slimmer sightlines, the IR 521 Storefront Framing System represents an inspired fusion of performance capabilities and design possibilities.(Courtesy Kawneer)The systems distinctive features include:Non-thermal, thermal, and ultra-thermal options to suit different climate needsPre-glazed framing members that allow for complete in-shop fabrication and glazing, saving on installation costs and improving project efficiencyAvailable in wide range of painted finishes The IR 521 Storefront Framing System offers a pre-glaze option, as well as non-thermal, thermal and ultra-thermal frame types. Pre-glaze units can be completely fabricated and glazed in the shop, reducing installation costs and keeping your project on track.Kawneers first-ever pre-glazed impact storefront system offers Missile Level E enhanced impact protection against windborne debris.(Courtesy Kawneer)The system meets the testing standards for windborne debris set out in ASTM E-1886 and E-1996 and Florida Building Code protocols TAS 201, TAS 202 and TAS 203. Florida Product Approval (FPA) and Texas Department of Insurance (TDI) approvals.Along with an ultra-thermal option and more robust configurations, the IR 521 Storefront Framing System delivers versatility, durability and superior thermal performance.This product is available using low carbon aluminum, with a minimum of 50 percent recycled content and the remaining primary aluminum is sourced from a hydroelectric smelter. The IR 521 has Kawneers full material transparency statement available and is going through the Environmental Product Declaration (EPD) review process.0 Comments 0 Shares 10 Views

WWW.ARCHPAPER.COMIntroducing Kawneers new IR 521 / 521T / 521UT Storefront Framing System: Where protection meets perfectionKawneers new IR 521 Storefront Framing System offers the reliability of a Kawneer storefront system with exceptional innovation to meet industry needs. Kawneer has brought together the elements you need to enhance storefront projects in one unique framing system. Reimagining interiors and exteriors with sleek looks and slimmer sightlines, the IR 521 Storefront Framing System represents an inspired fusion of performance capabilities and design possibilities.(Courtesy Kawneer)The systems distinctive features include:Non-thermal, thermal, and ultra-thermal options to suit different climate needsPre-glazed framing members that allow for complete in-shop fabrication and glazing, saving on installation costs and improving project efficiencyAvailable in wide range of painted finishes The IR 521 Storefront Framing System offers a pre-glaze option, as well as non-thermal, thermal and ultra-thermal frame types. Pre-glaze units can be completely fabricated and glazed in the shop, reducing installation costs and keeping your project on track.Kawneers first-ever pre-glazed impact storefront system offers Missile Level E enhanced impact protection against windborne debris.(Courtesy Kawneer)The system meets the testing standards for windborne debris set out in ASTM E-1886 and E-1996 and Florida Building Code protocols TAS 201, TAS 202 and TAS 203. Florida Product Approval (FPA) and Texas Department of Insurance (TDI) approvals.Along with an ultra-thermal option and more robust configurations, the IR 521 Storefront Framing System delivers versatility, durability and superior thermal performance.This product is available using low carbon aluminum, with a minimum of 50 percent recycled content and the remaining primary aluminum is sourced from a hydroelectric smelter. The IR 521 has Kawneers full material transparency statement available and is going through the Environmental Product Declaration (EPD) review process.0 Comments 0 Shares 10 Views -

BUILDINGSOFNEWENGLAND.COMHills Library Andover Newton Theological School // 1895The Hills Library is a formal building standing at the summit of Institution Hill, so-named as the home of the Newton Theological Institution (and most recently as the Andover Newton Theological School). The library was constructed in 1895 from plans by architects Henry H. Kendall and Edward F. Stevens of the firm, Kendall & Stevens. Designed in 1894 in the Neo-Classical style, the library has a stately portico in the Ionic order with a pediment above. The building is constructed of yellow brick with stone and terracotta trimmings with banks of vertical windows. The library would be added onto at the rear, with the main entrance later closed for an accessible entrance in a rear addition. The building is now known as the Hanns Sachs Memorial Library for the current owners and stewards, the Boston Psychoanalytic Society & Institute (BPSI).0 Comments 0 Shares 10 Views